Supply Plenum Connection

Attach the supply plenum to the furnace

outlet duct connection flanges. This is

typically through the use of "S" cleat

material when a metal plenum is used.

The use of an approved flexible duct

connector is recommended on all instal-

lations. This connection should be

sealed to prevent air leakage.

If a matching cooling coil is used, it may

be placed directly on the furnace outlet

and sealed to prevent leakage. Follow

the coil instructions for installing the supply plenum.

On all installations a removable access panel should be pro-

vided in the outlet duct such that smoke or reflected light would

be observable inside the casing to indicate the presence of

leaks in the heat exchanger. This access cover shall be at-

tached in such a manner as to prevent leaks.

Return Duct Connection

Return air may enter the furnace through the side(s) or bottom

depending on the type of application. See the specific type

application installation for details. Be sure to see the "Filters"

section of this instruction.

FILTERS (UPFLOW/HORIZONTAL)

All applications require the use of a filter. This may be through the

use of any of the following accessory or field supplied methods:

1.

Internal Side Filter With Retainer - 1BF0302 (Upflow)

This provides a cleanable, high velocity type filter and

retainer hardware for mounting inside the furnace cabinet.

2.

External Side Return Filter Rack - 1SR0301. (Upflow)

This provides a 16x25 cleanable, high velocity type filter

and attaches to the furnace side panel and the return air

duct. The filter may be easily replaced.

3.

Internal Mount Bottom Return Filter Accessory (Upflow) -

1BF0301-304 This provides a cleanable, high velocity type

filter and retainer hardware for mounting inside the furnace

cabinet. This type filter requires removing the furnace

blower compartment cover to change the filter.

4.

External Bottom Return/End Return Horizontal, Filter Rack

Accessory - 1HF0301-304 Provides a cleanable, high

velocity type filter and rack. Attaches to the end of the

furnace and provides duct flanges.

5.

Field Supplied Filter and Mounting System.

A return air filter grille or duct mounted filter may be

provided. The following minimum sizes are recom-

mended.

NOTE: Air velocity through throw-away type filters may not

exceed 300 feet per minute. All velocities over this require

the use of high velocity filters.

Side Return

Locate and knock out the square corner locaters. These indi-

cate the size of the cutoff to be made in the furnace side panel

(see Figure 4).

Install the side filter rack following the instructions provided with

that accessory. If a filter(s) is provided at another location in the

return air system, the ductwork may be directly attached to the

furnace side panel.

NOTE: Some accessories such as electronic air cleaners and

pleated media may require a larger side opening.

CAUTION: All installations must have a filter installed.

The return duct may be attached to the furnace by "S-cleat",

bend tabs or other approved methods. Be sure to seal the duct

to the furnace to prevent air leakage.

Those applications over 1800 CFM require either return from

two sides, or bottom. For bottom only application, see data and

notes on page 21.

Where the return duct system is not complete, the return

connection must run full size to a location outside the utility

room or basement. For further details, consult Section 5.3 (Air

for Combustion and Ventilation) of the National Fuel Gas Code,

ANSI Z223.1, or CAN/CGA B149.1 or .2, Installation Code -

latest editions.

Bottom Return

Converting the furnace to open bottom return requires remov-

ing the bottom closure plate. Use the following steps.

1. Remove the upper access door and blower compart-

ment door.

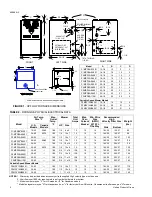

FIGURE 4 - SIDE RETURN CUTOUT MARKINGS

IAMON

80

D

D

RECOMMENDED SIZE FOR FIELD SUPPLIED

HIGH VELOCITY FILTERS

Furnace CFM

FILTER

Size

Sq. inches

800

12 x 27

300

1200

16 x 27

400

1600

20 x 27

500

2000

25 x 27

625

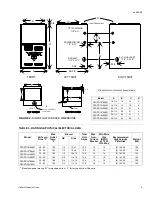

FIGURE 5- BOTTOM RETURN OPENING

FRONT OF

FURNACE

CORNER

MARKINGS

B

A

2

2-1/8

28-1/2

FRONT

22-1/2

CUT FLOOR

OPENING

Furnace

Width

8

12

18

22

12-1/4

16-1/4

22-1/4

26-1/4

A

B

Cut-Out

Width

NOTE: The bottom opening shown in Fig. 5 will provide a

support for an internal mount filter. The airflow will, how-

ever, be less than that indicated by the data on page 21.

(See Note)

UPFLOW APPLICATION

650.69-N3

Unitary Products Group

7