WARNING: If manifold pressure is too high, an over-fire con-

dition exists which could cause heat exchanger failure. If

the manifold pressure is too low, sooting and eventual

clogging of the heat exchanger could occur.

5. Once the correct gas pressure to the burners has been

established, turn the gas valve knob to OFF and turn the

electrical supply switch OFF; then, remove the pressure

tap at the gas valve and re-install the plug using a com-

pound (on the threads) resistant to the action of LP gases.

6. Turn the electrical and gas supplies back on, and, with the

burners in operation, check for gas leakage around the

plug with a soap and water solution.

WARNING: Be sure that the gas valve pressure regulator cap

is replaced.

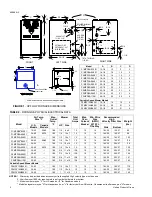

ADJUSTMENT OF TEMPERATURE RISE

The temperature rise, or temperature difference between the

return air and the heated air from the furnace, must be within

the range shown on the furnace rating plate and within the

application limitations shown in Table 1. After the temperature

rise has been determined, the cfm can be calculated.

After about 20 minutes of operation, determine the furnace

temperature rise. Take readings of both the return air and the

heated air in the ducts, about six feet from the furnace where

they will not be affected by radiant heat.

Increase the blower speed to decrease the temperature rise;

decrease the blower speed to increase the rise.

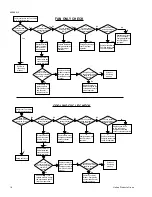

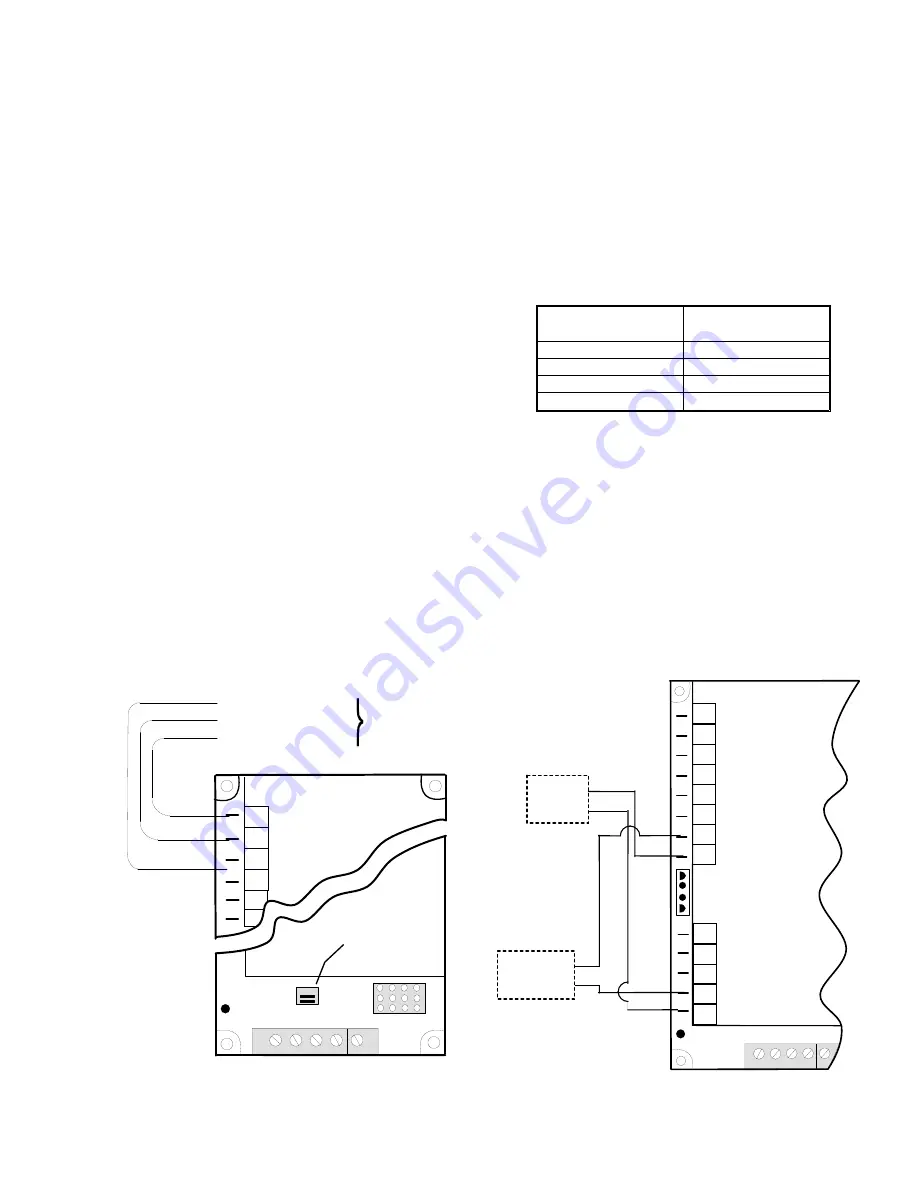

All direct-drive blowers have multi-speed motors. The blower

motor speed taps are located in the control box in the blower

compartment. Refer to Figure 15 and the unit wiring label to

change the blower speed.

You may select a heating speed and a cooling speed. They may

be the same speed or a different speed.

To use the same speed tap for heating and cooling, the "heat"

terminal and "cool" terminal must be connected using a jumper

wire and connected to the desired motor lead. Place all unused

motor leads on "Park" terminals. Two are provided.

CAUTION: Do not energize more than one motor speed at a

time or damage will result.

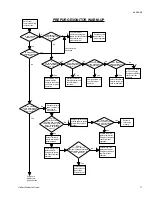

ADJUSTMENT OF FAN-OFF CONTROL SETTINGS

This furnace is equipped with a time on/time off heating fan

control. The fan "on" is fixed at 30 seconds. The fan "off" is field

adjustable from 60 to 180 seconds. The fan "off" is factory set

to 60 seconds.

The fan-off setting must be long enough to adequately cool the

furnace, but not so long that cold air is blown into the heated

space. The fan-off timing may be adjusted by setting the option

switches located (refer to Figure 15) on the control board as

follows:

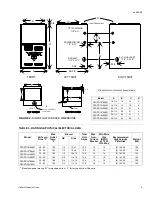

ACCESSORY CONNECTIONS

The furnace control will allow power switching control of various

accessories. See Figure 16 for connection details.

Electronic Air Cleaner Connection

Two 1/4" spade terminals (AC and AC N) for electronic air

cleaner connections are located on the control board. The

terminals provide 120 VAC (1.0 amp maximum) during circu-

lating blower operation.

Humidifier Connection

Two 1/4" spade terminals (HUM and HUM N) for humidifier

connections are located on the control board. The terminals

provide 120 VAC (1.0 amp maximum) during heat speed

operation of the circulating blower.

COOL

HEAT

PARK

PARK

XFMR

LINE

HUM

EAC

XFMR

EAC

LINE

CIR

HUM

120 VOLT

ELECTRONIC

AIR CLEANER

EAC HOT

HUM HOT

BLK

BLK

WHI

WHI

120 VOLT

HUMIDIFIER

FIGURE 16 - ACCESSORY CONNECTIONS

COOL

HEAT

PARK

XM

BLK - HIGH SPEED

BLU - MEDIUM SPEED

RED - LOW SPEED

BLK

BLU

RED

MOTOR LEADS

FAN OFF

ADJUSTMENT

SWITCHES

ON

OFF

1

2

LINE

PARK

FIGURE 15 - TYPICAL HEAT/COOL SPEED TAP

CONNECTIONS

To Delay Fan-Off By:

Set Switch

1 2

60 Sec.

On On

90 Sec.

On Off

120

Sec.

Off On

180

Sec.

Off Off

650.69-N3

Unitary Products Group

13