YORK INTERNATIONAL

6

ELECTRICAL DATA (Continued)

NOTES

1. MRC is Maximum Running Current, the maximum continuous current at any operating point in the rating range. Also referred to as MCA,

or Minimum Current Ampacity to be furnished by the installer.

2. The recommended disconnect switch is based on a minimum of 115% of the summation rated load amps of all the loads included in the

circuit, per N.E.C. 440 - 12A1.

3. Minimum fuse size is based on 150% of the largest motor RLA plus 100% of the remaining RLAs (U.L. Standard 1995, Section 36.1).

Minimum fuse rating = (1.5 x largest compressor RLA) + other compressor RLAs + (# fans x each fan motor FLA).

4. Maximum dual element fuse size is based on 225% maximum plus 100% of the rated load amps for all other loads included in the circuit,

per N.E.C. 440-22. Maximum fuse rating = (2.25 x largest compressor RLA) + other compressor RLAs + (# fans x each fan motor FLA).

5. Minimum circuit breaker is 150% maximum plus 100% of rated load amps included in the circuit, per circuit per U.L. 1995 Fig. 36.2.

Minimum circuit breaker rating = (1.5 x largest compressor RLA) + other compressor RLAs + (# fans x each fan motor FLA).

6. Maximum circuit breaker is based on 225% maximum plus 100% of the rated load amps for all loads included in the circuit, per circuit,

per U.L. 1995 Fig. 36.2. Maximum circuit breaker rating = (2.25 x largest compressor RLA) + other compressor RLAs + ( # fans x each

fan motor FLA).

7. The Incoming Wire Range is the minimum and maximum wire size that can be accommodated by unit wiring lugs. The (1), (2), or (3)

indicate the number of termination points or lugs which are available per phase. Actual wire size and number of wires per phase must

be determined based on ampacity and job requirements using N.E.C. wire sizing information. The above recommendations are based

on the National Electric Code and using copper connectors only. Field wiring must also comply with local codes.

8. A ground lug is provided for each compressor system to accommodate field grounding conductor per N.E.C. Article 250-54. A control

circuit grounding lug is also supplied. Incoming ground wire range is #6 - 350 MCM.

9. The field supplied disconnect is a Disconnecting Means as defined in N.E.C. 100.B, and is intended for isolating the unit from the

available power supply to perform maintenance and troubleshooting. This disconnect is not intended to be a Load Break Device.

10. Two-Compressor machines with single-point power connection, and equipped with Star-Delta Compressor motor starters, must also

include Factory-provided circuit breakers in each motor control center. 3 & 4 Compressor machine equipped with Star-Delta compressor

motor starter, must also include factory-provided circuit breakers in each motor control center.

11. Consult factory for Electrical Data on units equipped with High Static Fan Option. High Static Fans are 3.5 kW each.

12. FLA for Low Noise Fan motors is 4.1 A.

OPTIONAL 380V / 50HZ / 3Ø SINGLE POINT POWER SUPPLY CONNECTION

AND INTERNAL UNIT CIRCUIT BREAKERS

One Field Provided Power Supply Circuit to the chiller. Field connections to Power Terminal Block or Non-Fused Disconnect

in Option Panel. Internal Branch Circuit Protection (Breakers) per Motor Control Center

FIELD SUPPLIED WIRING

MODEL

FIELD PROVIDED POWER SUPPLY

FACTORY PROVIDED (LUGS) WIRE RANGE

YCAS

MRC

MIN NF

OVER-CURRENT PROTECTION

13

TERMINAL BLOCK

NF SERVICE DISC. SWITCH

(MCA

1)

DISC SW

2

MIN.

3, 5

MAX.

4, 6

(LUGS) WIRE RANGE

7

RATING

2

(LUGS) WIRE RANGE

7

RATING

2

0373SB

296

400

300

350

# 1 - 500

380

(2) 3/0-250

400

0403SB

321

400

350

400

(2) # 2 - 300

550

(2) 3/0-250

400

0453SB

375

400

400

450

(2) # 2 - 300

550

(2) 3/0-250

400

0503SB

430

600

450

500

(2) # 1 - 500

760

(3) 2/0-400

630

0543SB

387

400

400

450

(2) # 2 - 300

550

(2) 3/0-250

400

0573SB

455

600

500

500

(2) # 1 - 500

760

(3) 2/0-400

630

0623SB

493

600

500

600

(2) # 1 - 500

760

(3) 2/0-400

630

0653SB

464

600

500

500

(2) # 1 - 500

760

(3) 2/0-400

630

Summary of Contents for MILLENNIUM YCAS0373

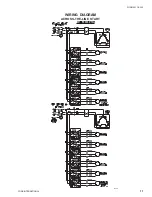

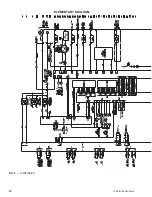

Page 11: ...FORM 201 18 W2 11 YORK INTERNATIONAL LD03228 WIRING DIAGRAM ACROSS THE LINE START...

Page 12: ...YORK INTERNATIONAL 12 FIG 1 CONTINUED ELEMENTARY DIAGRAM...

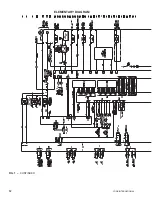

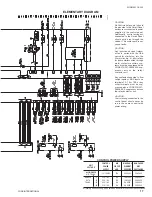

Page 15: ...FORM 201 18 W2 15 YORK INTERNATIONAL WIRING DIAGRAM WYE DELTA START LD03229...

Page 16: ...YORK INTERNATIONAL 16 FIG 2 CONTINUED ELEMENTARY DIAGRAM...

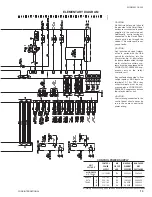

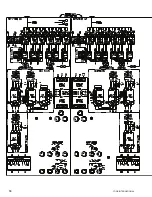

Page 18: ...YORK INTERNATIONAL 18...

Page 19: ...FORM 201 18 W2 19 YORK INTERNATIONAL LD03280...

Page 20: ...YORK INTERNATIONAL 20 LEGEND LD03281...

Page 21: ...FORM 201 18 W2 21 YORK INTERNATIONAL LD03282 LD03283 LD03284...

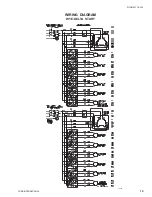

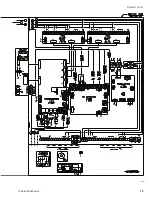

Page 22: ...YORK INTERNATIONAL 22 CONNECTION DIAGRAM SYSTEM WIRING LD03230 LD03231 LD03232...

Page 23: ...FORM 201 18 W2 23 YORK INTERNATIONAL COMPRESSOR TERMINAL BOX LD03233...