FORM 160.73-N1 (904)

27

YORK INTERNATIONAL

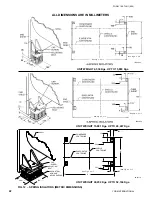

FIG. 16 –

MOTOR CONNECTIONS (ELECTRO MECHANICAL STARTER APPLICATION)

NOTES:

A. Requires passing motor lead thru current transformer (CT) once

before connecting to power supply.

B. Requires passing motor lead thru CT twice before connecting to

power supply.

C. Requires passing motor lead thru CT three times before

connecting to power supply.

COMPRESSOR MOTOR FIELD CONNECTION DIAGRAM

LD00710

3 PHASE

MOTOR RATED LOAD AMPS

MOTOR

CT RATIO

VOLTAGE

50 / 60 Hz 200:1 350:1 700:1 1400:1

200-600 65-111

A

112-224

A

225-829

A

830-1790

A

11-18

C

2300-4160

19-37

B

124-264

A

265-518

A

38-123

A

hav ing a clearance hole for a 3/8" bolt, motor ter mi nal

lugs are not furnished.

Chiller with Solid State Starter or

Variable Speed Drive

A chiller equipped with a factory mounted Solid State

Start er or Vari able Speed Drive does not require wiring

to the com pres sor motor. The motor power wiring is

factory con nect ed to the Solid State Starter or Variable

Speed Drive (or an optional factory in stalled disconnect

switch). See Field Wiring Diagram. All wiring to the

control pan el and the oil pump starter is com plet ed by

the factory. A control trans form er is furnished with the

Solid State Starter or Vari able Speed Drive.

INSULATION

(SEE PRODUCT DRAWINGS FORM 160.52-PA1)

DO NOT

fi

eld insulate until the unit has

been leak test ed under the su per vi sion

of the YORK rep re sen ta tive.

Insulation of the type speci

fi

ed for the job, or minimum

thick ness to prevent sweat ing of 30°F (-1°C) surfaces

should be fur nished (by others) and applied to the

evap o ra tor shell, end sheets, liquid feed line to

fl

ow

cham ber, com pres sor suc tion connection, and evaporator

liquid heads and con nec tions. The liquid head

fl

ange

in su la tion must be re mov able, to allow head re mov al for

the tube main te nance. De tails of areas to be insulated

are given on the Product Drawing.

Units are furnished factory anti-sweat insulated on or der

at additional cost. This includes all low tem per a ture

sur fac es except the two (2) cooler liquid heads.

INSTALLATION CHECK –

REQUEST FOR START-UP SERVICE

The services of a YORK representative will be fur nished

to check the installation and supervise the initial start-

up and operation on all chillers installed within the

Con ti nen tal United States.

After the unit is installed, piped and wired as described

in this Instruction, but before any attempt is made to start

the unit, the YORK District Of

fi

ce should be ad vised so

that the start-up service, included in the con tract price,

can be sched uled. Noti

fi

cation to the YORK of

fi

ce

should be by means of Installation Check List and

Request, Form 160.49-CL1, in triplicate.