FORM 160.73-N1 (904)

25

YORK INTERNATIONAL

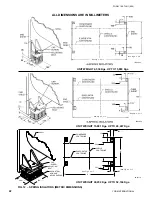

FIG. 14 – TYPICIAL REFRIGERANT VENT PIPING

Stop Valves

Stop valves may be provided (by others) in the

evap o ra tor and condenser water piping adjacent to the

unit to fa cil i tate main te nance. Thermometer wells and

pres sure taps should be provided (by others) in the piping

as close to the unit as pos si ble to facilitate operating

check.

Flow Switches

Thermal type water

fl

ow switches are factory mounted in

the chilled and condensed water nozzles and are factory

wired to the OptiView control panel. These solid-state

fl

ow sensors have a small internal heating element and

use the cooling effect of the

fl

owing

fl

uid to sense when

an adequate

fl

ow rate has been established.

Drain and Vent Valves

Drain and vent valves (by others) should be installed

in the connections provided in the evaporator and

con dens er liquid heads. These connections may be

piped to drain if desired.

Checking Piping Circuits and Venting Air

After the water piping is completed, but before any wa ter

box insulation is applied. Tighten and torque to main tain

between 30 and 60 ft. lbs. (41 and 81 N·m) the nuts on

the liquid head

fl

ang es. Gasket shrinkage and han dling

dur ing tran sit cause nuts to loosen. If water pres sure is

ap plied before tightening is done, the gas kets may be

damaged and have to be replaced. Fill the chilled and

condenser water circuits, operate the pumps man u al ly

and care ful ly check the evaporator and condenser wa ter

heads and piping for leaks. Repair leaks as nec es sary.

Before initial operation of the unit both water circuits

should be thoroughly vented of all air at the high

points.

REFRIGERANT RELIEF PIPING

Each unit is equipped with pressure relief valves lo cat ed

on the condenser and on the evap o ra tor for the pur pose

of quick ly relieving excess pres sure of the re frig er ant

charge to the atmosphere as a safety pre cau tion in case

of an emer gen cy, such as

fi

re.

Refrigerant relief vent piping (by others), from the re lief

valves to the outside of the building, is required by code

in most areas and should be installed on all chill ers. The

vent line should be sized in accordance with the ANSI/

ASHRAE-15, or local code.

The vent line must include

a dirt trap in the vertical leg to intercept and permit clean

out and to trap any vent stack con den sa tion. The piping

MUST be arranged to avoid strain on the relief valves,

using a

fl

exible connection, if nec es sary.

UNIT PIPING

Compressor lubricant piping and system external pip ing

are factory installed on all units shipped as sem bled. On

units shipped dismantled, the following piping should

be com plet ed under the supervision of the YORK

rep re sen ta tive: (1) the lubricant piping to oil sump and

oil evaporator and sys tem oil return connections using

ma te ri al fur nished. See Form 160.73-N3.

FLANGED JOINT

TO PERMIT PIPING

DISASSEMBLY

CONDENSATION

TRAP

DUAL RELIEF

VALVES

VENT TO ATMOSPHERE

SUPPORT VENT PIPING TO AVOID

STRAIN ON RELIEF PIPING

FLEXIBLE CONNECTOR

CONDENSER

COOLER

SEE NOTE

NOTE:

SHELLS MAY BE FURNISHED WITH

ONE

OR

TWO RELIEF VALVES,

DEPENDING ON SHELL SIZE.

LD03863

EVAPORATOR