YORK INTERNATIONAL

32

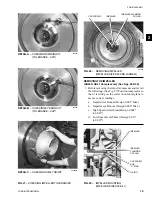

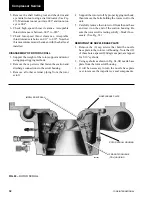

5. Remove the shaft locking tool and check rim and

eye radial runout using a dial indicator. (See Fig.

27). Maximum runout on rim is .003" and runout on

eye is .002".

6. Check high-speed thrust clearance. Acceptable

thrust tolerance is between .009" to .020".

7. Check low-speed thrust clearance. Acceptable

thrust tolerance is between .011" to .019". Note that

this measurement must be taken with the shaft seal

installed.

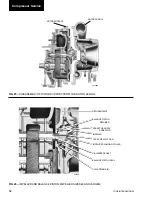

DISASSEMBLY OF ROTOR SCROLL

1. Support the weight of the rotor support and motor

using proper rigging methods.

2. Remove the cap screws that fasten the suction and

discharge connections to the scroll housing.

3. Remove all other external piping from the rotor

scroll.

4. Support the rotor scroll by proper rigging methods;

then remove the bolts holding the rotor scroll to the

unit.

5. Carefully remove the rotor scroll from the unit base

and rest it on the end of the suction housing. Be

sure the rotor scroll is resting solidly – block if nec-

essary. (See Fig. 63)

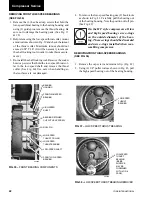

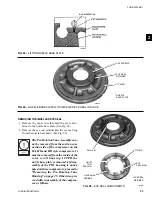

REMOVING THE NOZZLE BASE PLATE

1. Remove the (6) cap screws that hold the nozzle

base plate to the rotor scroll housing. Note that (2)

of these holes, spaced 180 degrees apart, are tapped

for 5/16" eyebolts.

2. Using eyebolts as shown in Fig. 64, lift nozzle base

plate from the rotor scroll housing.

3. It will be necessary to turn the nozzle base plate

over to remove the impeller eye seal components.

FIG. 63 –

ROTOR SCROLL

26439A3

PRE-ROTATION VANE

(PRV) HOUSING

ROTOR SCROLL HOUSING

NOZZLE BASE PLATE

IMPELLER EYE SEAL

Compressor Service