YORK INTERNATIONAL

24

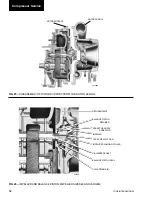

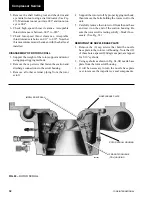

REMOVING BEARING HOUSING AND GEARS

Bearing Housing

1. Remove (2) of the cap screws that hold the bearing

housing to the rotor support and insert (2) 3/8" guide

pins as shown in Fig. 45. Also insert (3) 3/8" eye-

bolts as shown. On the HF style compressors, the

(2) 1/2" cap screws shown in Fig. 46 are used to

secure the dowel pins which align the bearing hous-

ing with rotor support. Remove dowel pins.

2. Attach proper rigging, and remove the remaining

cap screws.

Remove the bearing housing, using

care so that the compressor is not

damaged and that no injury occurs to

service personnel as the bearing hous-

ing is quite heavy.

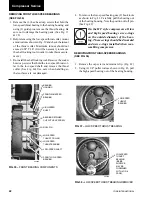

Gears

1. Remove the high-speed reverse thrust bearing, high-

speed thrust collar, and high-speed forward thrust

bearing.

2. Remove the shaft locking tool.

3. Remove the compressor shaft seal. DO NOT re-

move the rear low-speed bearing.

4. Rotate the high-speed gear as necessary to free

the gear teeth while pulling the gear from the rotor

support.

5. To remove the low-speed gear, use a 1/2" - 13 eye-

bolt in the end of the shaft and pull the gear out of

the rotor support.

Before re-assembly, be sure the compressor hous-

ing is absolutely clean by cleaning it with an ap-

proved safety solvent and blowing it dry with com-

pressed air. Inspect all wearing surfaces and re-

place parts as necessary. See

“Cleaning And

Checking Wearing Parts”

, page 6. Discard “O”

rings and replace with new.

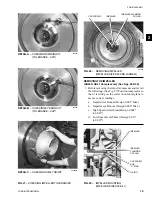

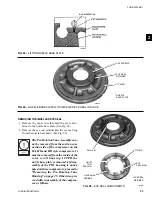

REAR LOW-SPEED BEARING

(SEE FIG. 47)

Removal

To remove/replace the rear low-speed bearing, proceed

as follows:

1. Remove the compressor coupling spool as described

on previous pages under

“Motor Removal And

Replacement”

. Also remove the compressor hub

from the compressor shaft.

2. Remove the compressor shaft seal as described on

previous pages.

3. Remove the screw holding the retainer clip to the

compressor.

4. Using the (2) 1/4" puller rods as shown in Fig. 48,

remove the bearing from the compressor.

5. Inspect the bearing. See

“Cleaning And Check-

ing Wearing Parts”

, page 6. Replace with new

bearing if necessary.

EYEBOLTS

GUIDE PINS

DOWEL PINS

EYEBOLT

26329A

FIG. 45 –

REMOVING BEARING HOUSING

Compressor Service

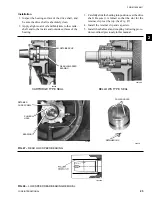

FIG. 46 –

HF BEARING HOUSING DOWEL PINS

00590VIP

DOWEL PINS

LOCATED UNDER

1/2" CAP SCREWS