035-15241-003 Rev. A (201)

16

Unitary Products Group

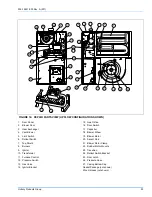

ACCESSORIES

A humidifier or electronic air cleaner may be used with this

furnace. All accessories should be wired according to the

manufacturer's instructions.

The furnace control board has a terminal marked EAC, which

may be used to power an electronic air cleaner accessory.

This terminal is energized with 115 volts whenever the fur-

nace circulating air blower is operating in either heating or

cooling speed.

The furnace control board has a terminal marked HUM, which

may be used to power an humidifier accessory. This terminal

is energized with 115 volts whenever the wall thermostat calls

for heat.

Make sure that the total load on the furnace transformer does

not exceed 40 VA, including gas valve, furnace relays, acces-

sories, and air conditioner loads.

Do not attempt to wire an electronic air cleaner into the fur-

nace blower relay. Damage to the furnace blower motor may

result.

TWINNING

When two furnaces are installed using the same duct system,

it is very important that the two furnace circulating air blowers

operate simultaneously. If one blower starts before the sec-

ond blower, the duct system will become pressurized with air

and the second blower will be made to turn backwards. Dur-

ing heating operation, this will cause overheating of the sec-

ond furnace, possibly causing an unsafe condition and

damage to the furnace. The furnace control board has a ter-

minal marked TWIN which can be used to cause two furnace

blowers to operate together.

If two furnaces are to be twinned using a single wall thermo-

stat, connect an isolation relay as shown in Figure 12 below.

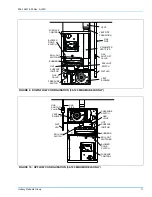

BLOWER MOTOR SPEED SELECTION

These furnaces are equipped with blowers, which have multi-

speed direct drive motors.

The blower speed selected is dependent upon the design

and static pressure loss of the duct system. The duct system

external static pressure includes the combined total of the

supply and return ducts and any plenum type air conditioning

coil if used.

The furnace must be adjusted to operate at or below the

maximum external static (in. W.C.), and within the air temper-

ature rise range as shown on the unit rating plate and in the

specification table.

Dependent upon the conditions in a particular installation, the

blower speeds may need to be changed to give the proper

operation on cooling or heating. The table above shows the

proper blower speed to use for cooling operation.

These leads should be connected in the control box to either

the heating terminal or the cooling terminal, depending on the

airflow desired. The unused motor speed lead(s) should be

connected to the terminals marked PARK on the blower con-

trol board in the furnace control box.

FIGURE 12: TWIN CONNECTION DIAGRAM

W

G

C

R

Y

TWIN

TO A/C

WALL THERMOSTAT

W

G

R

Y

ISOLATION

RELAY

FURNACE 2 CONTROL BOARD

W

G

C

R

Y

TWIN

FURNACE 1 CONTROL BOARD

SHOCK HAZARD -

Be sure electrical power to

furnace is turned off before changing motor

speeds.