035-15241-003 Rev. A (201)

12

Unitary Products Group

Unless prohibited by local codes, it is permissible to use a

flexible corrugated metal gas connector for the last section of

gas piping connected to the furnace gas valve. If a flexible

connector is used, it must be certified to be in compliance

with ANSI Standard Z21.24 or, in Canada, with Standard

CAN1-6.10.

Following installation of the piping, first ensure that the gas

control lever or switch on the gas valve is in the off position

and then pressurize the system with gas. Thoroughly check

the piping system for leaks.

The maximum and minimum gas supply pressure required at

the inlet of the gas control valve is shown on the unit rating

plate. When the furnace is in operation, the inlet pressure

must be within the limits shown.

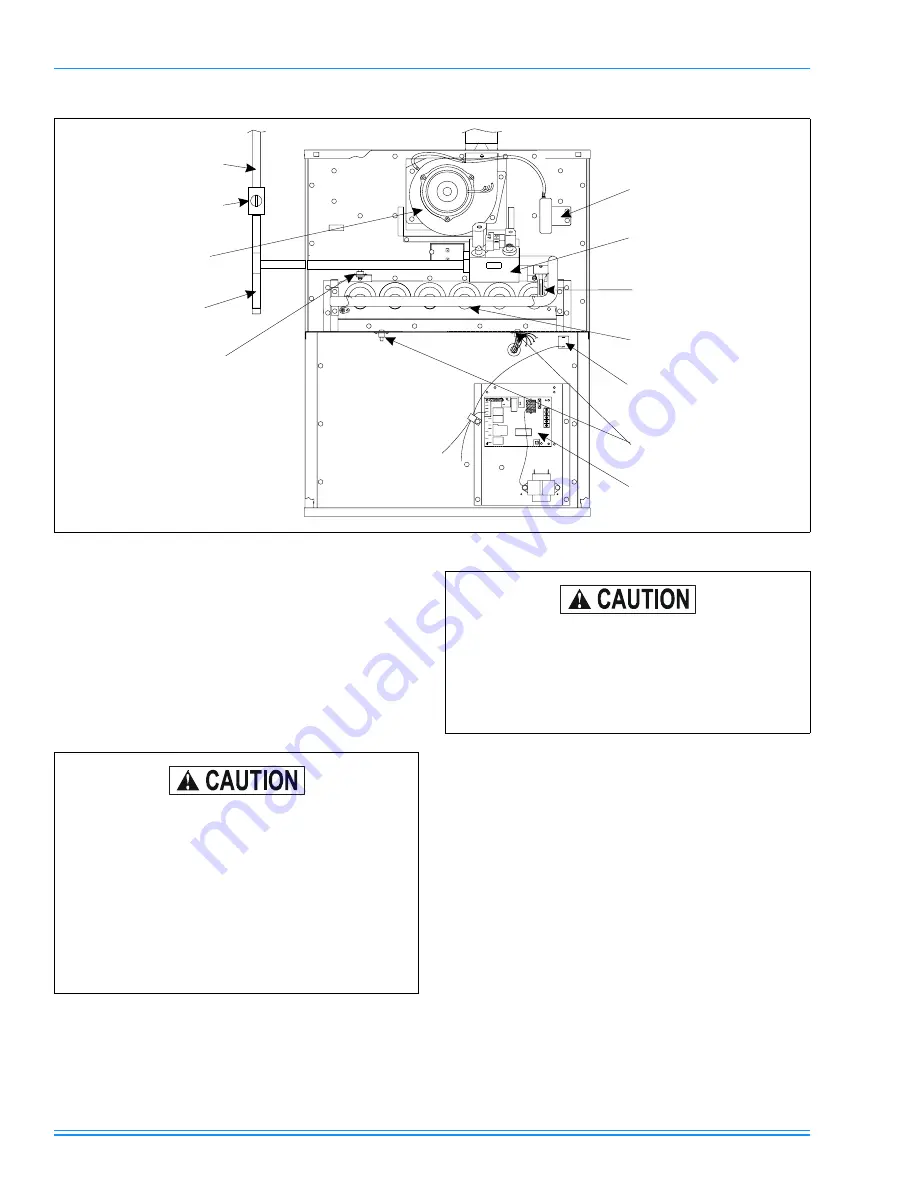

FIGURE 11: UPFLOW/HORIZONTAL (150 MBH MODEL ONLY)

BLOWER

DOOR

SWITCH

ROLL-OUT

SWITCHES

BURNERS

HOT

SURFACE

IGNITOR

GAS

VALVE

PRESSURE

SWITCH

GAS

PIPE

GAS

SHUT-OFF

VALVE

ROLL-OUT

SWITCH

DIRT

LEG

VENT

BLOWER

FURNACE

CONTROL

During pressure testing of the gas supply piping

system, observe the following to avoid fire, explo-

sion, asphyxiation, or damage to the appliance.

a.

If test pressure is less than or equal to 1/2 psig

(3.48 kPa)(14" W.C.), isolate the furnace by clos-

ing its individual manual shutoff valve.

b.

If test pressure is greater than 1/2 psig (3.48

kPa)(14" W.C.), the furnace and its individual

shutoff valve must be disconnected from the gas

supply system.

Never use an open flame to check for leaks. Fire

or explosion could occur. Since some leak solu-

tions, including soap and water, may cause corro-

sion or stress cracking, the piping must be rinsed

with water after testing unless it has been deter-

mined that the leak solution is non-corrosive.