035-15241-003 Rev. A (201)

10

Unitary Products Group

DOWNFLOW (50-125 MBH MODELS ONLY)

Filters must be mounted in a location where they are easily

accessible for replacement, either behind a central return air

grille or in a filter box mounted on top of the furnace as shown

in Figure 7. A filter rack is supplied with the furnace. The table

lists the minimum filter sizes.

UPFLOW

An appropriately sized permanent cleanable or disposable fil-

ter shall be used. The filter should be installed in a side return

filter rack or, if bottom return is to be used, in a suitable filter

box under the furnace. Filters must be located external to the

furnace casing. See Figure 8.

HORIZONTAL

An appropriately sized permanent cleanable or disposable fil-

ter shall be used. The filter should be installed behind a return

grille or other location with easy access for filter change.

Locating the filter in a crawl space, attic or other inaccessible

location will result in filters not being changed as frequently

as recommended.

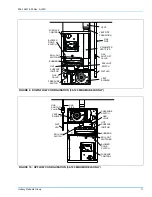

GAS PIPING

Before installing gas piping, check with local code authorities

for requirements concerning gas piping.

In the absence of local codes, follow the recommendations

contained in NATIONAL FUEL GAS CODE ANSI Z223.1 for

gas piping materials, pipe sizing, and the requirements for

installation. In Canada, refer to the latest edition of the CAN/

CGA-B149 Installation Code and local codes for specifics. It

is recommended that a gas cock shutoff valve be installed in

the gas supply line outside the casing, where it is readily

accessible, as close to the furnace as is practicable, as

shown in Figures 9, 10 and 11.

An 1/8 in. NPT (plugged) pressure tap for test gauge connec-

tion must be installed in the gas supply line immediately

upstream from the furnace, if local authorities do not allow

use of the pressure tap in the gas valve for this purpose.

Install a dirt leg at the bottom of any vertical riser or drop, as

close to the furnace as possible, to collect moisture and for-

eign material. Install a ground joint union just ahead of the gas

control valve. A typical downflow arrangement is shown in Fig-

ure 9. A typical upflow arrangement is shown in Figures 10, 11.

When making the connection at the gas control valve, use a

wrench on the inlet side of the valve to prevent any possible

twisting of the valve body, which could cause damage and

leaks. When making up pipe joints, use pipe thread com-

pound which is resistant to natural and LP (propane) gases.

FIGURE 7: DOWNFLOW FILTERS

(50-125 MBH MODELS ONLY)

INPUT

BTUH

Furnace

Width

Cleanable

Filter

Disposable

Filter

50,000

17-1/2

14 x 20

(2) 10 x 20

75,000

17-1/2

14 x 20

(2) 14 x 20

75,000

21

16 x 20

(2) 16 x 20

100,000

21

16 x 20

(2) 16 x 20

100,000

24-1/2

20 x 20

(2) 20 x 20

125,000

24-1/2

20 x 20

(2) 20 x 20

ACCESS

PANEL

FILTERS

FILTER

RACK

FIGURE 8: UPFLOW FILTERS

Use only the type of gas for which the furnace is

equipped. Using the wrong gas could create a

hazard, resulting in damage, personal injury or

death.

SIDE

RETURN FILTER

BOTTOM

RETURN FILTER