50

YORK INTERNATIONAL

CHECKING THE REFRIGERANT CHARGE

DURING UNIT SHUTDOWN

The refrigerant charge is specified for each CodePak

model (see Table 4). Charge the correct amount of re-

frigerant and record the level in the cooler sight glass.

The refrigerant charge should always be checked and

trimmed when the system is shut down.

The refrigerant charge level must be checked after the

pressure and temperature have equalized between the

condenser and cooler. This would be expected to be 4

hours or more after the compressor and water pumps

are stopped. The level should be at the center of the

sight glass + 1/4 inch (6.35 mm).

Charge the refrigerant in accordance with the method

shown under the “Refrigerant Charging”, on page 49.

The refrigerant level should be observed and the level

recorded after initial charging.

HANDLING REFRIGERANT FOR

DISMANTLING AND REPAIRS

If it becomes necessary to open any part of the refrigerant system for repairs, it

will be necessary to remove the charge before opening any part of the unit.

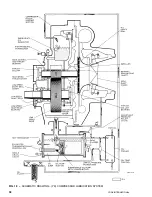

MEGGING THE MOTOR

While the main disconnect switch and compressor

motor starter are open, meg the motor as follows:

1. Using a megohm meter (megger), meg between

phases and each phase to ground (see Fig. 23);

these readings are to be interpreted using the graph

shown in Fig. 24.

2. If readings fall below shaded area, remove external

leads from motor and repeat test.

NOTE: Motor is to be megged with the starter at

ambient temperature after 24 hours of idle

standby.

LD01085

FIG. 23 – DIAGRAM, MEGGING MOTOR WINDINGS