8-5

IM 01C50C05-01EN

F0803-5.ai

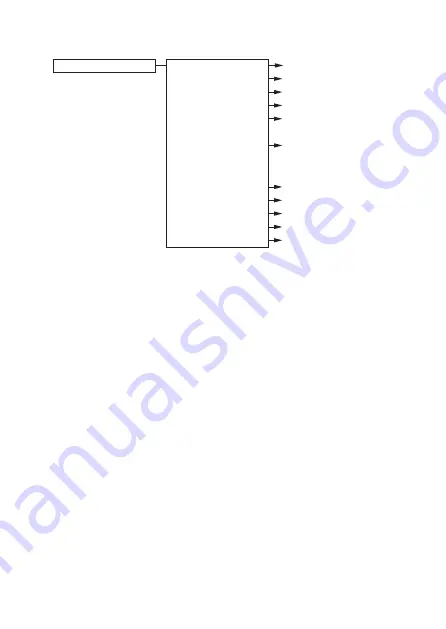

Setup

HART

Variable mapping

Range Variables

Process Sensor

Sensor 1 Setup

Sensor 2 Setup

Electronics/CJC Setup

Average Setup

Difference Setup

Trend Setup

Burst Setup

Trim Setup

Signal Condition

Output Condition

D1

D1

D1

D1

D2

Future use

D2

Future use

Future use

D2

D3

D4

D5

D6

D