IM 05D01D02-02E (2)

This manual describes key entries for operating the controller. For operations using external contact inputs, see “6. Terminal

Wiring Diagrams” in

Installation User’s Manual

. If you cannot remember how to carry out an operation during

setting, press the

S E T / E N T

key for more than 3 seconds. This brings you to the display (operating display) that appears at

power-on.

Contents

1. Setting Target Setpoint (SP)

2. Performing/Canceling Auto-tuning

3. Setting PID Manually

4. Setting Alarm Setpoints

5. Selecting Target Setpoint Numbers (SP.NO)

6. Switching between Run and Stop

7. Switching between AUTO and MAN

8. Manipulating the Control Output in Manual Operation

9. Troubleshooting

NOTE

Do not use the instrument generating strong magnetic field such as radio equipment and the like near the controller.

This may cause the fluctuation of the PV value.

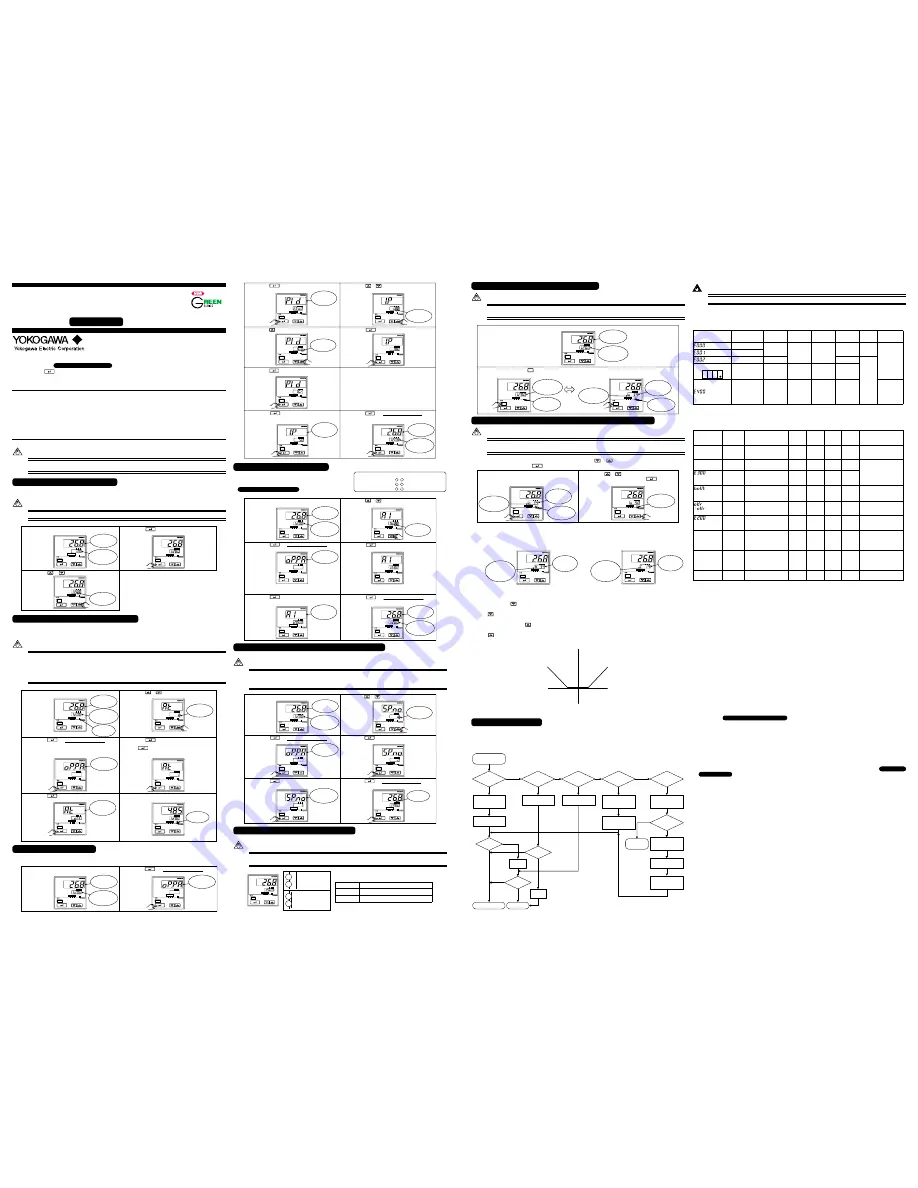

1. Setting Target Setpoint (SP)

The following operating procedure describes an example of setting 120.0 to a target setpoint. In automatic operation, the

controller starts control using set target setpoints.

NOTE

When the target setpoint is set through communication, the target setpoint cannot be changed by keystroke.

Press the or key to display the required

setpoint.

Bring the operating display into view (display

appears at power on).

Press the key once to register the setpoint.

1.

2.

3.

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

Displays PV.

Displays

target setpoint.

Blinks during

change.

2. Performing/Canceling Auto-tuning

Auto-tuning should be carried out after setting a target setpoint (SP). Make sure the controller is in automatic operation

mode (AUTO) and in running state (RUN) before carrying out auto-tuning. See “7. Switching between AUTO and MAN.” to

change to AUTO and “6. Switching between RUN and STOP,” to change to RUN.

NOTE

When on-off control is being used, auto-tuning cannot be carried out. Moreover, do not perform auto-tuning when

contolling any of following processes.

•

Control processes with quick response such as flow control or pressure control

•

Processes where even temporary output on/off results in inconvenience

•

Processes where a large output change at control element results in inconvenience

•

Processes where variations in PV may exceed an allowable range, adversely affecting product quality

Press the key for more than 3 seconds to call

up the menu “OP.PA”.

Bring the operating display into view (display

appears at power on).

1.

2.

Press the key five times to display the

parameter “AT”.

To cancel auto-tuning, set AT = OFF.

3.

Press the or key to display the required

setpoint. Tuning for 1.SP is AT = 1.

4.

Auto-tuning is complete when the MAN lamp goes off.

During auto-tuning, the panel indications become

as shown below.

Press the key once to register the setpoint.

(This starts auto-tuning.)

If the key is pressed when AT = OFF, auto-

tuning will be cancelled. In this case, PID contains

the value existing before auto-tuning.

5.

6.

S E T / E N T

S E T / E N T

S E T / E N T

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

Displays PV.

Displays

target setpoint.

MAN lamp

OFF.

Displays menu

“OP.PA”.

Displays

parameter

“AT”.

Blinks during

change.

MAN lamp

blinks.

3. Setting PID Manually

If you know the values to be set or if suitable PID constants cannot be obtained by auto-tuning, follow the procedure below

to set values.

Press the key for more than 3 seconds to call

up the menu “OP.PA”.

Bring the operating display into view (display

appears at power on).

1.

2.

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

Displays menu

“OP.PA”.

Displays PV.

Displays

target setpoint.

Press the or key to display the required

setpoint.

Press the key once to display the parameter

“1.P” (proportional band for 1.SP).

7.

6.

The same steps can be used for integral time (1.I) and

derivative time (1.D) that are displayed after this.

[TIP]

The PID parameter numbers set in step 4. should be

set as follows:

In case of PID for 1.SP, PID = 1Gr

In case of PID for 2.SP, PID = 2Gr

In case of PID for 3.SP, PID = 3Gr

In case of PID for 4.SP, PID = 4Gr

Press the key once to register the setpoints.

5.

Press the key once to register the setpoint.

8.

Press the key for more than 3 seconds.

This returns you to the display shown at power-on

(figure below).

9.

Press the key once to display “1Gr.”

4.

Press the key several times to display the

parameter “PID”.

3.

S E T / E N T

S E T / E N T

S E T / E N T

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

Displays

parameter

“1.P”.

Displays

target setpoint.

Displays PV.

Blinks during

change.

Displays

parameter

“PID”.

Blinks during

change.

4. Setting Alarm Setpoints

The following operating procedure describes an example of setting

160.0 to alarm-1 setpoint. Check alarm type before setting the alarm

setpoint. To change the type of alarm, see “5. Changing Alarm Type”

in

Initial Setting User’s Manual

.

Press the key twice to display the parameter

“A1”.

Bring the operating display into view (display

appears at power on).

Press the key once to register the setpoint.

Also configure the Alarm-2 Setpoint (A2) and Alarm-

3 Setpoint (A3) parameters that follow this step.

1.

3.

Press the or key to display the required

setpoint.

4.

5.

Press the key for more than 3 seconds.

This returns you to the display shown at power-on

(figure below).

Press the key for more than 3 seconds to call

up the menu “OP.PA”.

2.

6.

S E T / E N T

S E T / E N T

S E T / E N T

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

Displays PV.

Displays

target setpoint.

Displays menu

“OP.PA”.

Displays

parameter

“A1”.

Blinks during

change.

Displays PV.

Displays

target setpoint.

5. Selecting Target Setpoint Numbers (SP.NO)

The following operating procedure describes an example of changing a target setpoint number (SP.NO) from 1 to 2.

NOTE

If a target setpoint number has been switched using contact input, when the contact input is on, that number cannot

be selected by keystroke.

When using target setpoint ramp setting function, PV tracking works if the target setpoint number is switched.

Press the key for more than 3 seconds to call

up the menu “OP.PA”.

Press the key once to register the setpoint.

Press the key for more than 3 seconds. This

returns you to the display shown at power-on

(figure below).

Bring the operating display into view (display appears

at power on).

1.

2.

5.

6.

4.

Press the key several times to display the

parameter “SP.NO”

Press the or key to display the required

setpoint.

3.

S E T / E N T

S E T / E N T

S E T / E N T

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

SP2 lamp

ON.

Displays PV.

Displays

target setpoint.

Displays menu

“OP.PA”.

Displays

parameter

“SP.NO”.

Blinks during

change.

6. Switching between Run and Stop

Switching between the RUN and STOP states can be performed only using external contact input.

NOTE

When the controller is shipped from the factory, it is configured so that switching between the RUN and STOP

states cannot be performed. To make the switching possible, configure the DIS setup parameter as “DIS = 4”.

18

20

18

20

When the controller is stopped, input and outputs are

as follows:

When the controller is stopped, control output relay is

“STOP.”

Stop of operation

when ON

Start of operation

when OFF

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

PV input

Displays PV.

Control output

Preset output value (factory-set default: 0%)

Alarm output

ON in the event of an alarm

Alarm output terminals

Factory-set defaults

Alarm-1 (terminal numbers )............PV high limit alarm

Alarm-2 (terminal numbers )............PV low limit alarm

Alarm-3 (terminal numbers )............PV high limit alarm

-

6

7

-

5

7

-

4

7

7. Switching between AUTO and MAN

NOTE

If AUTO and MAN have been switched using contact input, when the contact input is ON, switching between

AUTO and MAN cannot be achieved by keystroke.

1.

Bring the operating display into view (display appears at power on).

2.

Each time you press the key on the front panel of the instrument, AUTO and MAN is switched alternately.

In automatic operation

In manual operation

A/M

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

Displays PV.

Displays

target setpoint.

Displays

target setpoint.

MAN lamp

ON.

Displays

output value.

%

Displays

output-value

symbol “o”.

MAN lamp

OFF.

8. Manipulating the Control Output in Manual Operation

NOTE

Control output cannot be changed if the controller is stopped. In this case, the preset output value (setup parameter

PO) will be output.

A control output value is linked with a display value changed using the

or

key. Note that the control output changes

as displayed without requiring the

S E T / E N T

key.

Bring manual operating display into view. For

switching to manual operation, see “

7. Switching

between AUTO and MAN ”.

1.

Press the or key to change a control output

value. You don’t need to press the key.

2.

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

MAN lamp

ON.

MAN lamp

ON.

Displays

output value.

%

Displays

output-value

symbol “o”.

■

Manipulating the Control Output during Heating/Cooling Control

Either of the following two displays appears when the mode is switched to MAN during heating/cooling control.

■

Heating-side OUT display

■

Cooling-side OUT display

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

P V

MAN

A / M

S P

AL1

2

3

SP

2

3

4

S E T / E N T

Symbol “H”

represents the

heating-side

output.

Heating-side

output

%

Symbol “C”

represents the

cooling-side

output.

Cooling-side

output

%

●

Controller behavior and control output manipulation when the dead band is positive

The following is an example when the DB parameter is set at 12.4%.

If you hold down the

key with the heating-side output under manipulation (i.e., cooling-side output C = 0.0%), the

heating-side output (H =) decreases. Consequently, both the heating-side and cooling-side outputs change to 0.0%. If you

keep the

key held down longer, you enter the state of manipulating the cooling-side output, and its value begins to

increase.

Inversely, if you hold down the

key with the cooling-side output under manipulation (i.e., heating-side output H = 0.0%),

the cooling-side output (C =) decreases. Consequently, both the heating-side and cooling-side outputs go to 0.0%. If you

keep the

key held down longer, you enter the state of manipulating the heating-side output, and its value begins to

increase.

Cooling-side

manipulated output

Heating-side

manipulated output

Output (%)

DB=12.4

Dead band:

Operating parameter DB

12.4

0

-12.4

Change in manipulated output when the dead band is positive

9. Troubleshooting

■

Troubleshooting Flow

If the operating display does not appear after turning on the controller’s power, follow the measures in the procedure below.

If a problem appears complicated, contact our sales representative.

Ask the vendor for repair.

Find the cause.

Totally

inoperable?

Yes

Yes

Yes

No

No

No

Is key

operation

faulty?

Yes

No

Yes

Check wiring on the

power supply

terminals.

Check the key lock

setting.

Is display

faulty?

Yes

No

Turn off power, and

then turn it on again.

Is I/O

signal faulty?

Yes

No

Check the

instrument’s I/O

specifications.

Check the supply

voltage.

Check the specifications

of I/O counterpart for

wrong polarity.

Check the

communication-related

parameters.

Check the specifications

of communication

counterpart.

Check

communication wiring.

Is

communication

link faulty?

No

Does the code

include a communication

option?

Yes

Normal?

Is

key lock

enabled?

Check the

instrument's suffix

code.

Yes

No

Correct?

Correct

errors.

Disable

key lock.

No communication

capability.

Is the instrument

defective?

IMPORTANT

Take note of the parameter settings when asking the vendor for repair.

■

Errors at Power On

The following table shows errors that may be detected by the fault diagnosis function when the power is turned on.

Error indication

(on PV display unit)

Description

of error

Remedy

Faulty RAM

Faulty ROM

System data error

PV decimal point blinks.

Faulty calibration

value

PV

Control

output

Alarm

output

Retransmission

output

Communi-

cation

None

OFF

0% or less

Stopped

0%

0% or less

or OFF

0%

Normal

action

Faulty

Contact us

for repair.

Normal action

(out of

accuracy)

Normal action

(out of

accuracy)

Normal action

(out of

accuracy)

Normal action

(out of

accuracy)

Parameter error

0%

Preset value

output

OFF

0%

Check and set

the parameters,

as they have

been set to the

limited values.

(E000)

(E002)

(E001)

(E400)

■

Possible Errors during Operation

The following shows possible errors occurring during operations.

Retransmis-

sion output

Commu-

nication

(-OVER)

(OVER) or

Error indication

(on PV display

unit)

Displays “RJC”

and PV

alternately

Faulty

Contact us for repair.

Faulty

Contact us for repair.

Check wires and

sensor.

Description

of error

RJC error

EEPROM

error

PV value blinks.

A/DC error

PV burnout

error

PV

Normal action

105%

Dependent on the BSL

parameter Up-scale: 105%

Down-scale: -5%

Measured

with RJC=OFF

Control

output

Normal

action

Normal

action

Preset

value

output

Preset

value

output

Alarm

output

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Remedy

Normal

action

Normal

action

Normal

action

Normal

action

Check process.

Check process. Press

any key to erase error

indication.

SP decimal

point blinks.

(on setpoint

display unit)

Check wires and

communication parameters,

and make resetting.

Recovery at normal receipt

Excessive PV

Out of -5 to

105%

Auto-tuning

failure

(Time-out)

Faulty

communi-

cation line

-5% or 105%

Normal action

Normal action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

Normal

action

All indications off

Faulty if power off/on does

not reset start the unit.

Contact us for repair.

All indications off

Check for abnormal power.

Runaway (due

to defective

power or

noise)

Power off

None

None

0% or less

or OFF

0%

OFF

OFF

0% or

less

0%

Stopped

Stopped

(E200)

(B.OUT)

(E300)

■

If a Power Failure Occurs during Operation

●

Momentary power failures shorter than 20 ms

The controller is not affected at all and continues normal operation.

●

Power failures of 20 ms or longer

• The alarm function of the controller continues to work normally. (Alarms with the stand-by feature temporarily return

to their stand-by state, however.)

• Setting parameters that have already been configured retain their settings.

• Auto-tuning is cancelled.

• After recovery from a power failure, control action resumes in the same mode as the one before the occurrence of the

power failure. The control output begins with the preset output value.

■

Troubleshooting When the Controller Fails to Operate Correctly

If your control tasks are not successful, check the preset parameters and controller wiring before concluding the controller to

be defective. The following show some examples of troubleshooting you should refer to in order to avoid the possibility of

other problems.

●

The controller does not show the correct measured input (PV).

• The UT350/UT320 controllers have a universal input.

The type of PV input can be set/changed using the parameter “IN”. At this point, the controller must be wired correctly

according to the selected type of PV input. Check the wiring first if the controller fails to show the correct PV. To do

this, refer to

Initial Settings

User’s Manual

.

With the parameters “RH”, “RL”, “SDP”, “SH” and “SL”, it is possible to scale the input signal and change its number

of decimal places. Also check that these parameters are configured correctly.

●

The controller does not provide any control output or the control output does not

change at all.

• The UT350/UT320 controllers have a universal output.

The type of control output can be set/changed using the parameter “OT”.

At this point, the controller must be wired correctly according to the selected type of control output. Check the wiring

first if the controller provides no control output. To do this, refer to “6. Terminal Wiring Diagrams,” in

Installation

User’s Manual

.

With the parameters “OH” and “OL”, it is possible to set/change the high and low limits of control output. The control

output may not change at all, however, because of restrictions on these parameters. Also check the restrictions on these

parameters.

• The control output can only be changed when the controller is in the MAN mode.

If the MAN lamp is off (i.e., the controller is in the AUTO mode), you cannot change the control output using key

operation.

●

The control output does not change soon after the target setpoint SP has been

changed.

• If this happens, check the setpoint of the parameter “C.MD”. In cases where fixed-point control is selected as the PID

control mode (C.MD = 1), tracking based on the I-term works to prevent the control output from changing suddenly

even if the target setpoint SP is varied.

The control output therefore may appear to be working incorrectly at first; however it gradually adapts itself to the new

target setpoint.

User’s

Manual

IM 05D01D02-02E

3rd Edition: Sep 30, 2004

Models UT350 / UT320

Digital Indicating Controllers

User’s Manual

Operations