Rev.

10/22/01

HGM300/RDM800

mini

manual.doc

8

6)

Use

the

left/right

and

up/down

keys

to

change

the

temperature

and

the

ì ENTERî

key

to

complete

the

action.

7)

ì CURRENT

PPMî

This

function

cannot

be

accessed.

8)

Press

the

ì LOG

INTERVALî

button

only

if

the

interval

is

to

be

reduced

from

the

1440-minute

(once

every

24

hours)

factory

setting

to

a

lower

setting.

(At

the

1440

minute

setting

the

HGM300

will

record

the

observed

PPM

level

once

every

24

hours.

This

can

be

reset

to

lower

numbers

to

trend

a

problem

in

a

given

zone.)

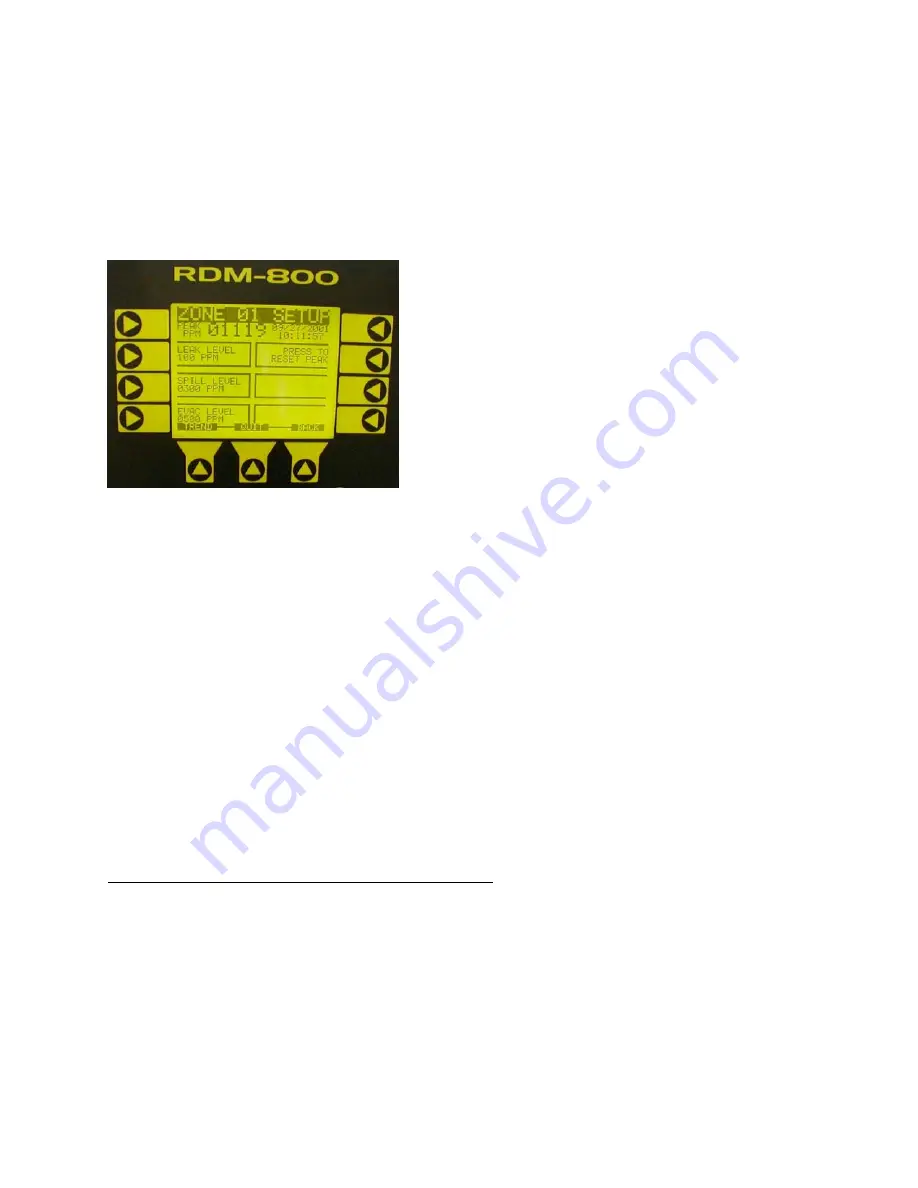

9)

Press

ì MOREî

This

takes

you

to

the

second

zone

set

up

screen.

Press

ì LEAK

LEVELî

button.

Use

left/right

keys

to

move

across

and

up/down

keys

to

readjust

leak

alarm

PPM

level

to

desired

PPM

level.

10)

Press

ì SPILL

LEVELî

button.

Repeat

as

in

step

8.

11)

Press

ì EVACUATE

LEVELî

Button.

Repeat

as

in

step

8.

Note:

The

evacuate

level

must

be

greater

than

or

equal

to

the

spill

level,

which

must

be

greater

than

or

equal

to

the

leak

level.

12)

Press

ì RESET

PEAKî

button.

Use

the

to

clear

the

previous

peak

PPM

displayed

for

this

zone.

This

key

is

used

to

clear

the

peak

PPM

for

this

zone,

which

is

displayed

at

the

top

of

this

screen.

The

peak

PPM

gives

the

PPM

level,

time

and

date

of

the

highest

refrigerant

readings

since

the

unit

was

last

cleared

(or

started,

if

the

reading

has

never

been

cleared).

The

peak

PPM

reading

along

with

the

TREND

DATA

can

be

a

powerful

diagnostic

tool

in

detecting

small

leaks

before

they

become

large

leaks.

13)

To

move

to

the

next

zone

set

up

screen

press

the

right

keypad

button.

Use

the

ì BACKî

button

to

move

to

the

first

zone

set

up

screen.

Repeat

steps

2

to

13

to

program

the

second

zone.

Repeat

as

necessary

for

all

zones

in

monitor.

To

return

to

the

SYSTEM

SCREEN,

press

QUIT

then

press

SYSTEM.

PROGRAMMING

USING

THE

HGM300

PC

SOFTWARE

Note

ñ

There

are

two

versions

of

software

and

firmware.

Version

1.0

generally

is

found

in

HGM300

serial

numbers

beginning

with

AJ00

to

serial

numbers

beginning

with

AF01

and

version

1.25

from

serial

numbers

beginning

with

AF01

forward.

If

an

RDM800

is

connected

to

the

unit

the

version

of

the

firmware

can

be

obtained

from

the

HGM300

Main

screen.

Insert

software

disk

into

PC.

Note:

The

PC

software

uses

COM1

by

default.

Therefore,

the

interface

cable

should

be

connected

to

the

port

configured

as

COM1

on

the

PC.

Also,

no

other

software

drivers

or

devices

in

the

PC

may

control

COM1

when

the

HGM300

software

is

in

use.

The

connection

is

made

through

a

standard

ì straight

throughî

serial

port

connection.

A

three-wire

connection

is

used

(RXD,

TXD,

and

GND).

No

hardware

flow

control

is

used.

The

HGM300

software

automatically

configures

COM1

to

match

the

HGM300

RS-232

communications

parameters.

Turn

on

power

to

HGM300.

SETUP

SCREEN

#

2

Archived

Document