9

OPERATION

I

MPORTANT:

Please check the amount of travel that the Residue Manager has

before

going to the field.

I

MPORTANT:

Check for clearance with the residue manager wheels. If the residue manager wheels can

make contact with the frame, tires, or hitch the Titan

™ Residue Manager could be damaged.

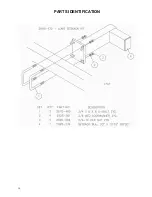

Level applicator as shown below.

Once the knives are at the desired depth, the machine must be leveled. A low front end will cause the front

knives to be in the ground deeper than the rear knives. Wi

th the knives in the soil, measure distance “A”

and “B” from level ground to the bottom of the frame – THIS DISTANCE MUST BE THE SAME. Once the

distance is obtained, step back approximately 50 feet and view the machine. The applicator should appear

level to the ground. If not, make certain the ground is level. The applicator can be leveled by changing the

position of the hitch clevis.

Set the coulter depth. The coulters are adjusted independent of the A. A. knives. Loosen the set screws on

the mounting bracket and slide the coulter shaft up or down to the desired height.

Do not run the coulters any deeper than what is needed to cut the residue. Running the coulters deeper

than necessary increases coulter wear. Coulters set too deep will decrease berm height by prefacturing the

soil in front of the knife.

MAINTENANCE

Regularly inspect the residue manager for loose or worn parts. Repair and replace as

needed.

Storing the Equipment

Store the machine in an area away from human activity

Store machine in RAISED position.

Install service locks on all wheel cylinders.

At the end of the season, the machine should be thoroughly inspected and prepared for

storage. Repair or replace any worn or damaged components to prevent down time at the

start of the next season. Store machine under cover with all parts in operating condition.

Clean machine thoroughly to remove all dirt, debris and crop residue, which would

hold moisture and cause rusting.

Inspect machine for worn or broken parts. See your Yetter Farm Equipment dealer

during the off-season so that parts or service can be acquired when machine is not

needed in the field.

Lubricate bearings as outlined in the Lubrication section

Paint all parts which are chipped or worn and require repainting.

Store machine in a clean, dry place with the planting unit out of the sun.

If the machine cannot be stored inside, cover with a waterproof tarpaulin and tie

securely in place.

Do not allow children to play on or around the machine

Summary of Contents for TITAN 2967-033A

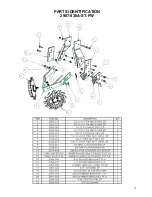

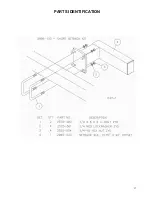

Page 10: ...10 PARTS IDENTIFICATION 2966 140 ST FW 2966 140 BW FW...

Page 11: ...11 PARTS IDENTIFICATION 2966 141 FW...

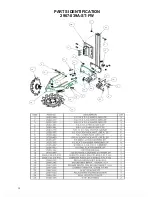

Page 12: ...12 PARTS IDENTIFICATION 2967 033A ST FW...

Page 13: ...13 PARTS IDENTIFICATION 2967 038A ST FW...

Page 14: ...14 PARTS IDENTIFICATION 2967 039A ST FW...

Page 15: ...15 PARTS IDENTIFICATION 2967 041A ST FW...

Page 16: ...16 PARTS IDENTIFICATION...

Page 17: ...17 PARTS IDENTIFICATION...

Page 18: ...18 NOTES...

Page 19: ...19 NOTES...

Page 20: ...20 2565 736_REV_H 06 2021...