9

Cable Wiring

9.1

Disassembly and Reassembly of Internal Wiring Harness

9-11

HW1485471

HW1485471

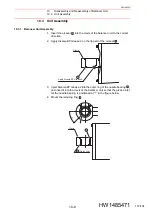

Reassembly

1. Connector Base

• Refer to

table 9-5 “Internal Wiring Harness Parts Checklist (Connec-

fig. 9-5 “Disassembly and Reassembly of the Internal

Wiring Harness (Connector Base)”

.

1. Put the internal wiring harness through the manipulator from the top

part of the S-head.

2. Connect the connector of the connector base box.

3. Connect [LAMP] and [External axis] sticking out from the connector

which are inserted into 4CN of the 1BC connector with the connector

sticking out from the internal wiring harness.

4. Mount the internal wiring harness on the connector base by using the

saddle

and saddle

, and tighten the hexagon socket head cap

screws

with the tightening torque shown in

. It must be

fixed in position with the white mark on the internal wiring harness

facing directly upward.

5. Mount the connector for the internal user I/O wiring harness together

with the gasket

on the connector base unit, and then tighten it with

pan-head sems screws

.

6. Connect the 1BC connector.

7. Mount the ground lead wires (3 wires) by using the cross head APS

bolts .

8. Cover the connectors with tube

, and then tie the openings of the

tube

by using the cable ties

.

9. Connect the grease hose to the back side of the connector base unit.

10. Mount the cross head APS bolts

, and then mount the connector

base on the manipulator.

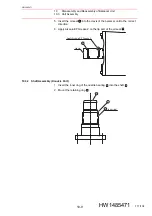

2. S-Head

• Refer to

fig. 9-4 “Disassembly and Reassembly of the Internal Wir-

table 9-4 “Internal Wiring Harness Parts

1. Mount the internal wiring harness on the plate

by using the

hexagon socket head cap screws

, and tighten them with the

tightening torque shown in

. Fix the white-marked part of the

internal wiring harness by using the cable ties

.

2. Connect the “IN” port and the “OUT” port of the multi-port connector of

the S-head to the “IN” connector and the “OUT” connector of the

internal wiring harness respectively.

3. Fix together the “IN” and “OUT” lead wires of the internal wiring

harness and the lead for the encoder of the S- and L-axis by using the

cable tie

.

4. Mount the cover

by using the hexagon socket head cap screws

, and tighten them with the tightening torque shown in

.

5. Insert the power connector to the S- and L-axis motor by aligning the

key position, and then turn the coupling nut on the cable side until it

makes a clicking sound. Confirm that the arrow marks on the

connector on the motor side and the connector on the wiring harness

side match.

6. Fix the internal wiring harness around the S-head with the cable ties

.

9

10

8

5

4

2

7

7

6

1

1

2

6

7

3

4

5

100/134