9-19

167109-1CD

HW1482308

9

Maintenance and Inspection

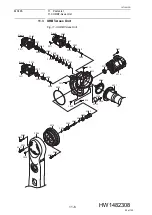

9.4 Gas Maintenance Procedure in the Gas Balancer

MS165

9.4.3.2 Gas Discharging Procedures

When Discharging All Gas

1. Move the manipulator to the home position and turn OFF the power

supply of the DX200.

2. Remove the cover and the hexagon socket head screw plug M6 with

flange, which are mounted to the gas inlet, and insert the quick

connector.

3. Connect the gas filling device to the quick connector after confirming

that the blowdown valve, needle valve, and gate valve of the gas filling

device are firmly closed.

4. Slowly open the needle valve.

5. Discharge gas a small amount at a time by slowly releasing the

blowdown valve.

6. Close the needle valve and blowdown valve, and then remove the gas

filling device from the quick connector.

7. Remove the quick connector and mount the cover, then tighten the

hexagon socket head screw plug M6 with flange by using a tightening

torque of 4.9 N•m (0.5 kgf•m).

8. Mount the cover and tighten the hexagon socket head cap screws M4

(length: 6mm) with a tightening torque of 2.8 N•m (0.29 kgf•m.)

9. Turn ON the power supply of the DX200.

When Discharging Gas for Adjusting Pressure

1. Move the manipulator to the home position and turn OFF the power

supply of the DX200.

2. Remove the cover and the hexagon socket head screw plug M6 with

flange, which are mounted to the gas inlet, and insert the quick

connector.

3. Connect the gas filling device to the quick connector after confirming

that the blowdown valve, needle valve, and gate valve of the gas filling

device are firmly closed.

4. Check the temperature of the gas balancer surface.

5. Slowly open the needle valve.

DANGER

Before discharging/filling the gas from/into the gas balancer, confirm

that the L-axis motor brake is appropriately functioning and L-axis is

firmly fixed so that it will not rotate. Failure to observe this may cause

very dangerous situation due to releasing of the L-axis motor brake.

Because the L-axis without retaining force leads the L-arm to rotate by

the lengthened or shortened gas balancer.

MANDATORY

•

When discharging the gas, the blowdown valve must not be fully

opened. Take time and discharge gas little by little. If the

blowdown valve is fully opened with high internal pressure, the non-

return valve in the gas balancer can be damaged.

80 of 100