6 MECHATROLINK Option Drive Parameters

YASKAWA ELECTRIC

TOBP C730600 49A V1000 Option MECHATROLINK-II Installation Manual

23

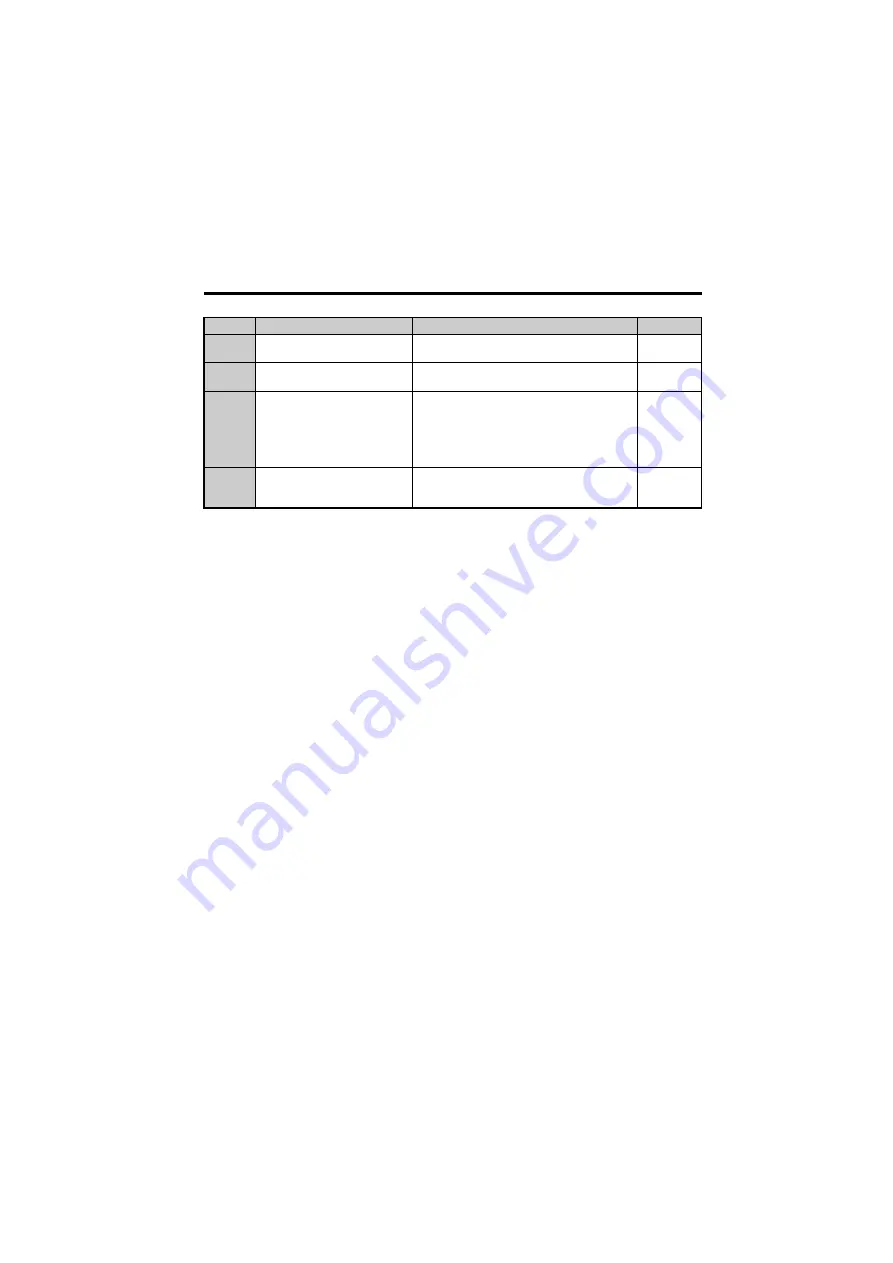

F6-23

MECHATROLINK Monitor

Selection (E)

0 to FFFFH

0

F6-24

MECHATROLINK Monitor

Selection (F)

0 to FFFFH

0

F6-25

Operation Selection at Watchdog

Error (E5)

0: Ramp to stop. Decelerate to stop using the

deceleration time in C1-02.

1: Coast to stop.

2: Fast Stop. Decelerate to stop using the

deceleration time in C1-09.

3: Alarm only.

1

F6-26

MECHATROLINK bUS Errors

Detected

Sets the number of option communication errors

(bUS).

2 to 10

2

<1> To start and stop the drive with the MECHATROLINK master device using serial communications, set b1-02 to 3.

To control the frequency reference of the drive via the master device, set b1-01 to 3.

<2> If set to 3, then the drive will continue to operate when a fault is detected. Take proper measures such as installing

an emergency stop switch.

<3> Power must be cycled in order for any setting changes to take affect.

<4> All station addresses must be unique. If set to 20 or 3F, a Station Address Error (AEr) will occur and the ERR light

will turn on.

<5> Setting byte 10 of INV_CTL to 0EH enables the register set by F6-23. Byte 11 and 12 of the response data enable

the register content set by F6-23.

Refer to the SI-T3/V Technical Manual for detail.

<6> Setting byte 10 of INV_CTL to 0FH enables the register set by F6-24. Byte 11 and 12 of the response data enable

the register content set by F6-24.

Refer to the SI-T3/V Technical Manual for detail.

No.

Name

Description

Default