EN 12

YASKAWA Europe TOEP_C710606_97A - AC Drive A1000 IP54READY - Quick Start Guide

3 Electrical Installation

3

Electrical Installation

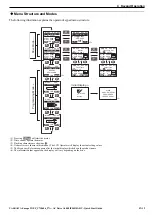

The figure below shows the main and control circuit wiring.

<1> Remove the jumper when installing a DC reactor. Models 4A0058 through 4A0165 come with a built-in DC reactor.

<2> Never short terminals SP and SN as doing so will damage the drive.

<3> Disconnect the wire jumper between H1 - HC and H2 - HC when utilizing the Safe Disable input.

Three-phase

power supply

200 to 400 V

50/60 Hz

R/L1

S/L2

T/L3

Main

Switch

Fuse

EMC

Filter

+

−

+

+

+

+

M

U/T

1

V/T

2

W/T

U

V

W

3

Ground

Terminals -, +1, +2, B1, B2 are

for connection options. Never

connect power supply lines to

these terminals

DC reactor

(option)

U

X

Thermal relay

(option)

+

−

+

+

+

+

+

−

U

X

S

1

S

2

S

3

S

4

S

5

S

6

S

7

MP

DM

DM

RP

A

1

A

2

A

3

0 V

AC

R

R

S

S

IG

H

1

H

2

HC

Drive

B

1

1

2

B

2

2 k

Ω

S

8

SC

0 V

0 V

AC

FM

AM

AC

E (G)

S

1

S

2

<1>

<3>

−

+

24 V

+

V

MA

M

1

M

2

MB

MC

Jumper

Braking resistor

(option)

Forward Run / Stop

Reverse Run / Stop

External fault

Fault reset

Multi-speed step 1

Multi-speed step 2

External Baseblock

Jog speed

Multi-function

digtial inputs

(default setting)

Sink / Source mode

selection wire link

(default: Sink)

CN5-C

CN5-B

CN5-A

Option card connectors

Pulse Train Input (max 32 kHz)

Shield ground terminal

Multi-function

analog/ pulse

train inputs

Power 10.5 Vdc, max. 20 mA

Analog Input 1 (Frequency Reference Bias)

-10 to +10 Vdc (20 k

Ω

)

Analog Input 2 (Frequency Reference Bias)

-10 to +10 Vdc (20 k

Ω

)

0 or 4 to 20 mA (250

Ω

)

Analog Input 3 / PTC Input

(Aux. frequency reference)

-10 to +10 Vdc (20 k

Ω

)

−

V

Power supply, -10.5 Vdc, max. 20 mA

Safety

switch

MEMOBUS/Modbus

comm. RS485/422

max. 115.2 kBps

Safe Disable inputs

Wire

jumper

Open

Safety relay /

controller

Termination resistor

(120

Ω

, 1/2 W)

DIP

Switch S2

Fault relay output

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function relay output (During Run)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

Multi-function pulse train output

(Output frequency)

0 to 32 kHz (2.2 k

Ω

)

Multi-function analog output 1

(Output frequency)

-10 to +10 Vdc (2mA) or 4 to 20 mA

Multi-function analog output 2

(Output current)

-10 to +10 Vdc (2mA) or 4 to 20 mA

EDM (Safety Electronic Device Monitor)

Main Circuit

Control Circuit

shielded line

twisted-pair shielded line

main circuit terminal

control circuit terminal

R/L1

S/L2

T/L3

Motor

Shielded

Cable

M

3

M

4

Multi-function relay output (Zero Speed)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

M

5

M

6

Multi-function relay output (Speed Agree 1)

250 Vac, max. 1 A

30 Vdc, max 1 A

(min. 5 Vdc, 10 mA)

SP

SN

AM

FM

V

I

V

I

DIP Switch S1

A2 Volt/Curr. Sel

DIP Switch S4

A3 Analog/PTC

Input Sel

PTC

AI

Off

On

DIP Switch S2

Term. Res. On/Off

Jumper S3

H1, H2

Sink/Source Sel.

Jumper S5

FM/AM Volt./Curr.

Selection

Terminal board

jumpers and switches

FM

+

−

AM

<2>