EN 4

YASKAWA Europe TOEP_C710606_97A - AC Drive A1000 IP54READY - Quick Start Guide

1 Safety Instructions and General Warnings

1

Safety Instructions and General Warnings

YASKAWA Europe supplies component parts for use in a wide variety of industrial applications. The selection and

application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA

accepts no responsibility for the way its products are incorporated into the final system design. Under no circumstances

should any YASKAWA product be incorporated into any product or design as the exclusive or sole safety control.

Without exception, all controls should be designed to detect faults dynamically and fail safely under all circumstances.

All products designed to incorporate a component part manufactured by YASKAWA must be supplied to the end user

with appropriate warnings and instructions as to the safe use and operation of that part. Any warnings provided by

YASKAWA must be promptly provided to the end user. YASKAWA offers an express warranty only as to the quality of

its products in conforming to standards and specifications published in the manual. NO OTHER WARRANTY,

EXPRESS OR IMPLIED, IS OFFERED. YASKAWA assumes no liability for any personal injury, property damage,

losses, or claims arising from misapplication of its products.

Scope of Delivery

IP54 ready drives are prepared for being mounting in a panel to achieve protection class IP54. The drives heatsink is

mounted outside the cabinet and not in IP54 area. An adequate sealing is attached to the drive with shipment.

Applicable Documentation

The following manuals are available for A1000 series drives:

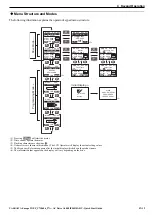

Drive Model Identification

A1000 Drive

Quick Start Guide

A1000 Series AC Drive Technical Manual

This manual provides detailed information on parameter settings, drive functions, and MEMOBUS/Modbus specifications. Use this manual to

expand drive functionality and to take advantage of higher performance features.

A1000 Series AC Drive Quick Start Guide (this book)

Read this manual first. This guide is packaged together with the product. It contains basic information required to install and wire the drive, in

addition to an overview of fault diagnostics, maintenance, and parameter settings. Use the information in this book to prepare the drive for a trial

run with the application and for basic operation.

YASKAWA AC Drive A1000

IP54 Ready

Quick Start Guide

MANUAL NO. TOEP C710616 27D

Type: CIMR-AC4A

Models: 400 V Class: 18.5 to 90 kW

To properly use the product, read this manual thoroughly and retain for

easy reference, inspection, and maintenance. Ensure the end user receives

this manual.

UAA - 0068

C I M R -

Drive

A1000

Series

No.

Region

Code

No.

Voltage Class

Environmental

Specification

Design

Revision

Order

No.

Customized

Specifications

A

Standard

4

A C 4

A

0 0 5 8

W

A

A

C

Europe

No.

Enclosure

Type

W

IP54 Ready

No.

A

Standard

3-phase, 380-480 Vac

Model Number