OPERATING TIPS

NOTE:

The edger requires a lot of power and should not be operated simultaneouslywith other

tools or utilities on the same household circuit.

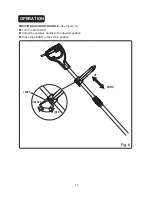

Set initial cut depth at 1” and set edge guide to the down posotion.

Before starting the edger line up the tool so the edger guide rests against the edge of the

paved surface. Both rear wheels should be on the paved surface when edging.

NOTE:

When there is heavy overgrowth of grass over the paved surface it may dragon the

guard. An initial cut may be require reducing the depth at cut.

To avoid kickback, lift the handle down so the blade is above the guard.

Turn switch ON and allow blade to spin without moving tool.

Slowly lift the handle to lower the blade. Find the edge of the paved surface and start

edging. Then move tool forward slowly along edge of paved surface, keeping the edge

guide pressed lightly against the pavement edge.

For the first edging of each season, it is best to move forward slowly because early in the

season grass is thickest. Subsequent edging will be completed more rapidly. If the tool slows

down, back it up an inch or two until the balde comes up to normal speed. During edging some

sparks may be generated from hitting stones. This is normal. Do not attempt to edge when the

grass or soil is wet or moist for electrical safety and to prevent clogging of the blade chamber.

If you must edge under conditions that causethe blade chamber to become clogged, release

trigger, wait for blade to come to complete stop, UNPLUG TOOL, open door and remove

clogged meterial with a stick. To continue to operate the tool in a clogged condition will

seriously overload the motor.

CAUTION:

Do not attempt to unclog the blade chamber by dropping or tapping the tool on the

ground. This can damage the unit. Keep hands clear of the edge guide andblade when

cleaning as these wear to a very sharp point during edging.

Make sure that other people and pets are at lease

5

0' away from the

work area.

OPERATION

20

WARNING:

Before landscaping or trenching, inspect and ensure there are no exposed

or buried cables, pipes or other objects that may create a hazard or interfere with operating

the edger. Set depth to only that required for the job. Do not overload. If tool slow down,

back up slightly and wait until blade comes backup to normal speed.

WARNING:

Summary of Contents for 060-3808-8

Page 26: ...26 PARTS LIST...