15

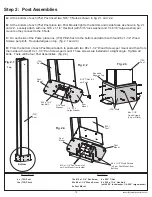

Step 4: Frame Assembly and Anchoring

Part 1

Fig. 4.1

A:

Move your Post Assemblies to the final location. Make sure the ground is flat and level before continuing

assembly.

B:

With one person at each Post stand two complete Post Assemblies. A third person places one Beam

Assembly against the outside of each Post, flush to the tops and outside corners. Notice bolt hole orientation on

the Beam Assembly. A fourth person attaches Beam to Post with one 3/8 x 8-1/2” Hex Bolt (with two 3/8” large

washers and one 3/8” lock nut) per Post. The distance from the outside of one Post to the outside of the second

Post should be 9’ 1-7/8” (2.791 m). (fig. 4.1, 4.2 and 4.3)

C:

Continue until all four Beam Assemblies are attached and the corners are tight together. (fig. 4.1 and 4.2) See

fig. 4.3 for accurate positioning of Posts.

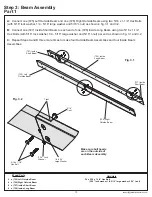

Fig. 4.2

Hardware

8 x 3/8 x 8-1/2” Hex Bolt (3/8” large washer x 2, 3/8” lock nut)

Note hole

orientation (on

bottom)

Fig. 4.3

3/8” Lock

Nut

3/8” Large

Washer

3/8” Large

Washer

3/8 x 8-1/2”

Hex Bolt

3/8 x 8-1/2”

Hex Bolt

Beam

Assembly

Beam

Assembly

Beam

Assembly

Post Assembly

Post

Assembly

Post

Assembly

Post

Assembly

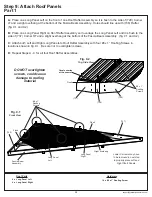

Plinth to Plinth

Plinth to Plinth

Post to Post

Post to Post

Plinth

Note hole

orientation (on

bottom)

11’ 7-7/8”

9’ 1-7/8”

8’ 1-3/8”

8’ 1-3/8”

2.473 m

2.791 m

2.473 m

3.553 m