13

•

Follow the original angle of grind as a guide. Make

sure that each cutting edge receives an equal

amount of grinding to prevent an unbalanced blade.

Balancing the Blade

•

The blade can be tested by balancing it on a round

shaft screwdriver. Remove metal from the heavy

side until it balances evenly. It is recommended that

the blade always be removed from the adapter

when testing for balance.

Installing the Blade

•

Before reinstalling the blade and the blade adapter

to the unit, lubricate the engine crankshaft and the

inner surface of the blade adapter with light oil.

•

Be sure to install the blade with the side of the

blade marked “Bottom” (or with part number) facing

the ground when the mower is in the operating

position.

•

Slide the blade adapter onto the engine crankshaft.

•

Place the blade on the adapter. Be certain the

blade is aligned and seated on the blade adapter

flanges.

•

Place blade bell support on blade. Make sure the

notches on the blade bell support are aligned with

small holes in the blade.

•

Replace hex bolt and tighten hex bolt to torque: 450

in. lbs. min., 600 in. lbs. max.

NOTE: To ensure safe operation of your mower,

periodically check the blade bolt for correct torque.

Replacing Rear Flap

•

To remove rear flap, cut off the flat end of the wire

rod which secures it to the deck.

•

Attach the new flap and new rod to deck, bending

the ends of the new rod over to secure to deck.

Storing Your Lawn Mower

The following steps should be taken to prepare your

lawn mower for storage.

•

Clean and lubricate mower thoroughly as described

in the lubrication instructions.

•

Refer to engine manual for correct engine storage

instructions.

•

Coat mower’s cutting blade with chassis grease to

prevent rusting.

•

Store mower in a dry, clean area. Do not store next

to corrosive materials, such as fertilizer.

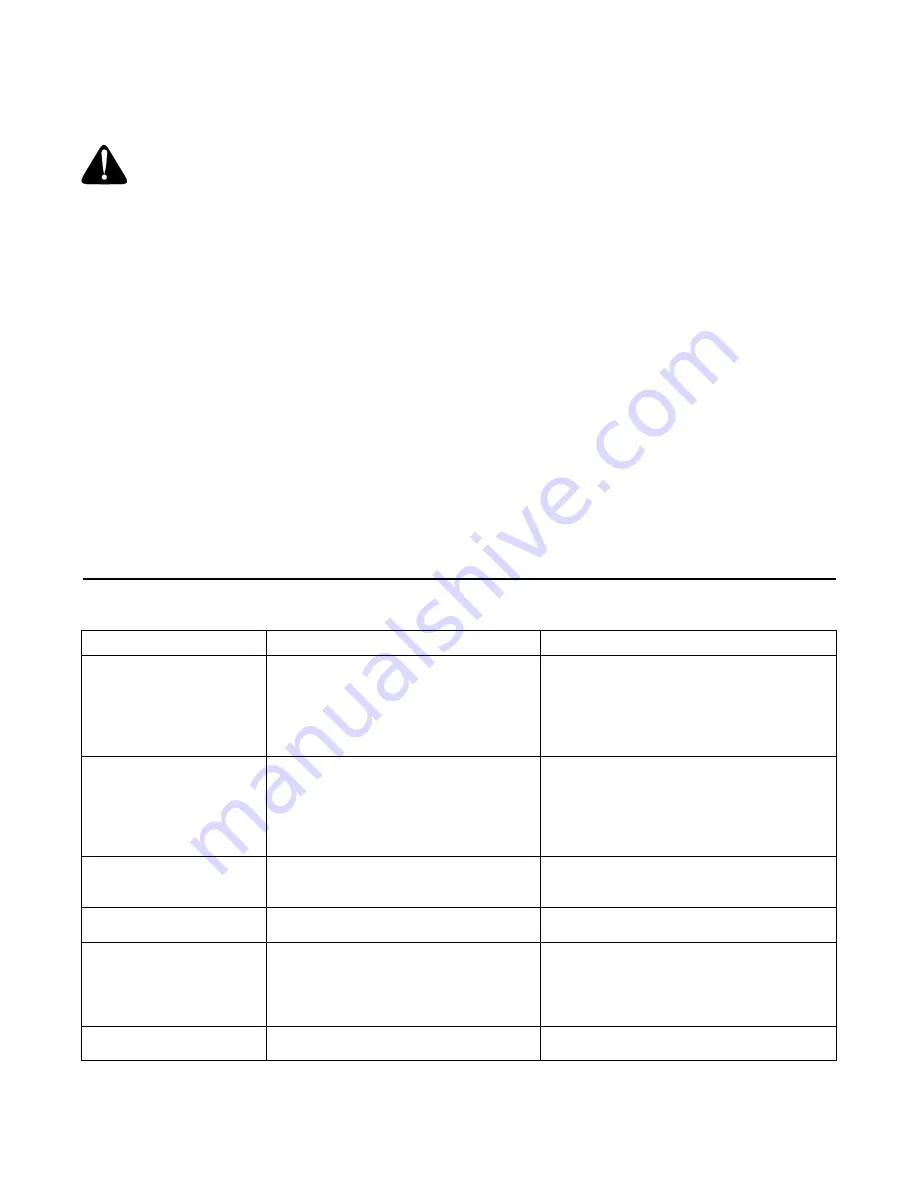

SECTION 9: TROUBLESHOOTING

WARNING:

An unbalanced blade will cause

excessive vibration when rotating at high

speeds. It may cause damage to the mower,

and could break causing personal injury.

Problem

Cause

Remedy

Engine fails to start

1.

Blade control handle disengaged.

2.

Spark plug wire disconnected.

3.

Fuel tank empty or stale fuel.

4.

Blocked fuel line.

5.

Faulty spark plug.

6.

Engine flooded

1.

Engage blade control handle.

2.

Connect wire to spark plug.

3.

Fill tank with clean, fresh gasoline.

4.

Clean fuel line.

5.

Clean, adjust gap, or replace.

6.

Wait a few minutes to restart, do not prime.

Engine runs erratic

1.

Spark plug wire loose.

2.

Blocked fuel line or stale fuel.

3.

Vent in gas plugged.

4.

Water or dirt in fuel system.

5.

Dirty air cleaner.

6.

Carburetor out of adjustment.

1.

Connect and tighten spark plug wire.

2.

Clean fuel line; fill tank with fresh gasoline

3.

Clear vent.

4.

Drain fuel tank. Refill with fresh fuel.

5.

Clean air cleaner.

6.

Adjust carburetor.

Engine overheats

1.

Engine oil level low.

2.

Air flow restricted.

3.

Carburetor not adjusted properly.

1.

Fill crankcase with proper oil.

2.

Remove blower housing and clean.

3.

Adjust carburetor.

Excessive vibration

1.

Cutting blade loose or unbalanced.

2.

Bent cutting blade.

1.

Tighten blade and adapter. Balance blade.

2.

Replace blade.

Mower will not mulch grass

1.

Wet grass.

2.

Excessively high grass.

3.

Dull blade.

1.

Do not mow when grass is wet; wait until

later to cut.

2.

Mow once at a high cutting height, then mow

again at desired height.

3.

Sharpen or replace blade.

Uneven cut

1.

Wheels not positioned correctly.

2.

Dull blade.

1.

Place all four wheels in same position.

2.

Sharpen or replace blade.