15

9

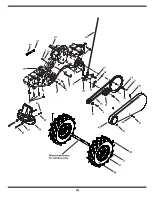

Illustrated

Parts List

Model 450

Series

To order replacement

parts, contact

1 (800) 800-7310

or visit

www.yardman.com

Ref.

Part No.

Part Description

1.

611-04074 Wheel Shaft Ass’y 33T

2.

611-0021

Tine Shaft Ass’y: 18T

3.

611-0128

Jack Shaft Ass’y

4.

611-0129

Input Shaft Ass’y

5.

617-0058

Rev. Idler Gear Ass’y: 30T

6.

617-0059

Tine Idler Gear Ass’y: 30T

7.

617-0060

Tine Input Sprocket Ass’y: 9T

8.

617-0061

Wheel Input Sprocket Ass’y: 10T

9.

617-0062

Gear Ass’y: 11T

10.

686-0108

R.H. Housing Ass’y

11.

710-0376

Hex Bolt 5/16-18 x 1” Lg.

12.

710-0599

Hex S-Tap Scr. 1/4- 20 x.5”

13.

710-0604A Hex S-Tap Scr. 5/16-18 x.625”

14.

710-3008

Hex Bolt 5/16-18 x.75”

15.

711-1349

Input Shaft

16.

712-0378

Hex Nut 7/16-20

17.

712-3004A Flange Nut 5/16-18

18.

713-0367

#420 Chain 1/2 Pitch x 50 Links

19.

713-0484

#50 Chain 5/8 Pitch x 54 Links

20.

716-0865

Snap Ring

21.

717-0853

Shifting Fork

22.

717-1582

Spur Gear 44T

23.

717-1583

Spur Gear 30T

24.

717-1584

Spur Gear 30T

25.

717-1585

Spur Gear 44T

26.

717-1587

Spur Gear 44T

Ref.

Part No.

Part Description

27.

717-1594

Spur Gear 16T

28.

721-0378

Seal 1.0 Shaft

29.

721-0379

Seal.75 Shaft

31.

726-0277

Taper Cap Ring

32.

732-0496

Compression Spring.50” Leg.

33.

736-0163

Thrust Wash. 1.03” I.D. X. 1.62”

34.

736-0351

Fl-Wash.76” I.D. x 1.5” O.D.

35.

736-0407

Bell-Wash .45” I.D. x 1.0”

36.

736-0518

Thrust Wash. .445 x 1.92 x .060

37.

736-3088

Fl-Wash. .635” I.D. x 1.59 O.D.

40.

738-0645

Detent Shaft 1/2” Dia.

41.

738-0648

Jack Shaft .625 x 2.385

42.

738-1013

Jack Shaft .625 x 5.0

43.

741-0124

Ball Bearing

44.

741-0420

Flange Bearing 1.0 x 2.5 x 1.38

45.

741-0421

Flange Bearing .75 x 2.5 x 1.38

46.

741-0563

Ball Bearing . 6692 x 5745 x .466

47.

741-0862

Detent Ball .250

48.

750-0258

Spacer .315

49.

750-0570

Spacer 1.0 I.D x 2.0 O.D. x .440

50.

750-0664

Spacer .505 I.D. x .88 O.D. x .440

51.

750-0671

Spacer .75 x 2.0 x .50

52.

786-0171

L.H. Chain Case Ass’y

53.

786-0238

Gear Positioner Bracket

686-0107

Gear Case Assembly Complete