CH1900 Series Electronic Control Installation Manual

Page 10

CH1900 Setup & Operation

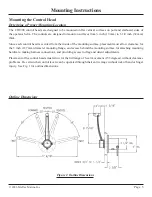

Figure 4: Drag Adjustment Location

Control Head Drag and Detent Adjustment

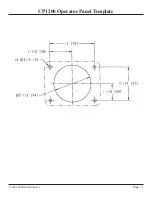

The detent adjustment screw is located on the inside end of each control head and requires a flat screwdriver for

adjustment. Detent firmness is increased by rotating the screw clockwise, and decreased with counterclockwise

rotation. It is recommended that adjustments be made by turning the screw in small increments (no greater than

½ turn), then feeling the resultant change at the handle.

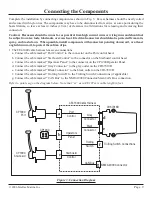

After all controls and system components have been mounted and interconnected, the system must be set up to

agree with the engines, transmissions, and operators preferences. For calibration, feature selection, and system

operation, refer to the Electronic Control System Installation Manual.

Each CH1900 control has been factory pre-set for comfortable detent and drag operation. However, if an operator

desires a different “feel” to the controls, adjustments can be made as follows:

Control lever drag:

The drag adjustment screw is located on the side of each control head. Adjustment requires a 5/32” hex allen

wrench. Drag is increased by rotating the screw clockwise, and decreased with counterwise rotation.

Be aware

that noticeable drag changes are made with relatively small adjustments to the screw.

It is recommended that

adjustments be made by turning the screw in small increments (no greater than 1/4 turn) and then feeling the

resultant change at the handle.

Caution: Turning the adjustment screw too tight can damage the drag adjustment.

Figure 5: Detent Adjustment Location

Drag

adjustment

screw

Detent

adjustment

screw