5. Inspection and servicing of basic engine parts

209

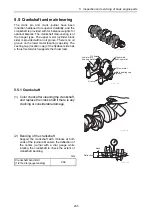

5.6 Camshaft and tappets

5.6.1 Camshaft

The camshaft is normalized and the cam and

bearing surfaces are surface hardened and

ground. The cams have a curve that minimized the

repeated shocks on the valve seats and

maximizes valve seat life.

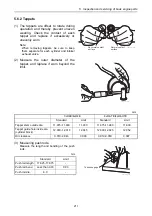

(1) Checking the camshaft side gap

Measure the thrust gap before disassembly.

As the cam gear is shrink-fitted to the cam, be

careful when replacing the thrust bearing.

(2) Measure the cam height, and replace

the cam if it is worn beyond the limit.

mm

Standard

Limit

Camshaft side gap

0.05-0.20

0.35

mm

3JH4E/4JH4E

4JH4-TE/4JH4-HTE

Standard

Limit

Standard

Limit

Cam height

Intake

38.600-38.800

38.350

39.800-40.000

39.550

Exhaust

37.800-38.000

37.550

Camshaft

Push rod

Tappet

Camshaft bushing

Camshaft gear

Thrust metal

006566-01E

Camshaft gear

Thrust metal

Side clearance

010643-00E

007709-00X

Summary of Contents for 3JH4E

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 14: ......

Page 34: ...1 General 14 1 4 Engine outline 1 3JH4E with KM35P marine gear 010300 00E ...

Page 35: ...1 General 15 2 3JH4BE with KM35A marine gear 010301 00E ...

Page 36: ...1 General 16 3 3JH4CE with SD50 SD40 sail drive 011211 00E ...

Page 37: ...1 General 17 4 3JH4ME Bobtail 011745 00E ...

Page 38: ...1 General 18 5 4JH4E with KM35P marine gear 010303 00E ...

Page 39: ...1 General 19 6 4JH4FE with ZF30M marine gear 010304 00E ...

Page 40: ...1 General 20 7 4JH4BE with KM35A2 marine gear 010305 00E ...

Page 41: ...1 General 21 8 4JH4B4E with KM4A1 marine gear 010306 00E ...

Page 42: ...1 General 22 9 4JH4CE with SD50 SD40 sail drive 011212 00E ...

Page 43: ...1 General 23 10 4JH4ME Bobtail 011746 00E ...

Page 44: ...1 General 24 11 4JH4 TFE with ZF30M marine gear 010308 00E ...

Page 45: ...1 General 25 12 4JH4 TBE with KM4A2 marine gear 010309 00E ...

Page 46: ...1 General 26 13 4JH4 THE with KMH4A marine gear 010310 00E ...

Page 47: ...1 General 27 14 4JH4 TIE with ZF25A marine gear 010311 00E ...

Page 48: ...1 General 28 15 4JH4 TCE with SD50 4T sail drive 010312 00X ...

Page 49: ...1 General 29 16 4JH4 HTFE with ZF30M marine gear B 010313 00E ...

Page 50: ...1 General 30 17 4JH4 HTBE with KM4A2 marine gear 010314 00E ...

Page 51: ...1 General 31 18 4JH4 HTHE with KMH4A marine gear 010315 00E ...

Page 52: ...1 General 32 19 4JH4 HTIE with ZF25A marine gear 010316 00E ...

Page 54: ...1 General 34 2 3JH4CE with SD50 SD40 sail drive 015032 00E ...

Page 55: ...1 General 35 3 4JH4 B E with KM35P KM35A2 marine gear 015033 00E ...

Page 56: ...1 General 36 4 4JH4B4E with KM4A1 marine gear 015034 00E ...

Page 57: ...1 General 37 5 4JH4FE with ZF30M marine gear 015035 00E ...

Page 58: ...1 General 38 6 4JH4CE with SD50 SD40 sail drive 015036 00E ...

Page 59: ...1 General 39 7 4JH4 TE with KM4A2 marine gear 015037 00E ...

Page 60: ...1 General 40 8 4JH4 TE with KMH4A and ZF25A marine gear 015038 00E ...

Page 61: ...1 General 41 9 4JH4 TE with ZF30M marine gear 015039 00E ...

Page 62: ...1 General 42 10 4JH4 TE with SD50 4T sail drive 015040 00E ...

Page 63: ...1 General 43 11 4JH4 HTE with KM4A2 marine gear 010327 00E ...

Page 64: ...1 General 44 12 4JH4 HTE with KMH4A and ZF25A marine gear 010328 00E ...

Page 65: ...1 General 45 13 4JH4 HTE with ZF30M marine gear 010329 00E ...

Page 348: ......

Page 349: ......

Page 350: ......