A05G069A

3

unused wires must be cut off or covered the metal ends.

⚫

Do not use a inverter as power supply. This cause damage of this product.

⚫

Must drain the pipe before installation. Install pump to a pressured pipe is

extremely high dangerous. It may cause a serious injure of operator.

⚫

Do not operate the pump in a pressure higher than specification , or fluid viscosity

>500 cP or temperature >60

℃

.

⚫

This unit is not suitable for all kind of fluid. Some solvents, extreme acid, high

oxidization high temperature or high viscosity fluid may cause malfunction of pump.

⚫

Wear a chemical protect mask and gloves before repair or maintenance.

⚫

Please do not try to modify the pump or use non-original parts. This damage pump

and cause warranty become invalid.

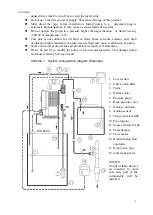

Scheme 1 System configuration diagram (Example)

1.

Level sensor

2.

Check valve/filter

3.

Pump

4.

Release valve

5.

Pressure gauge

6.

Back pressure valve

7.

Analog controller

8.

Analog sensor

9.

Target chemical tank

10.

Pipe injector

11.

Source chemical tank

12.

Pulse damper

13.

Flow sensor

14.

Digital/analog flow

controller

15.

Drain valve pipe

16.

Anit-siphon valve

NOTICE

:

Not all of these devices

are installed. In most

case only part of the

components will be

installed.

100~240V

AC

OR