19

Operational Precautions

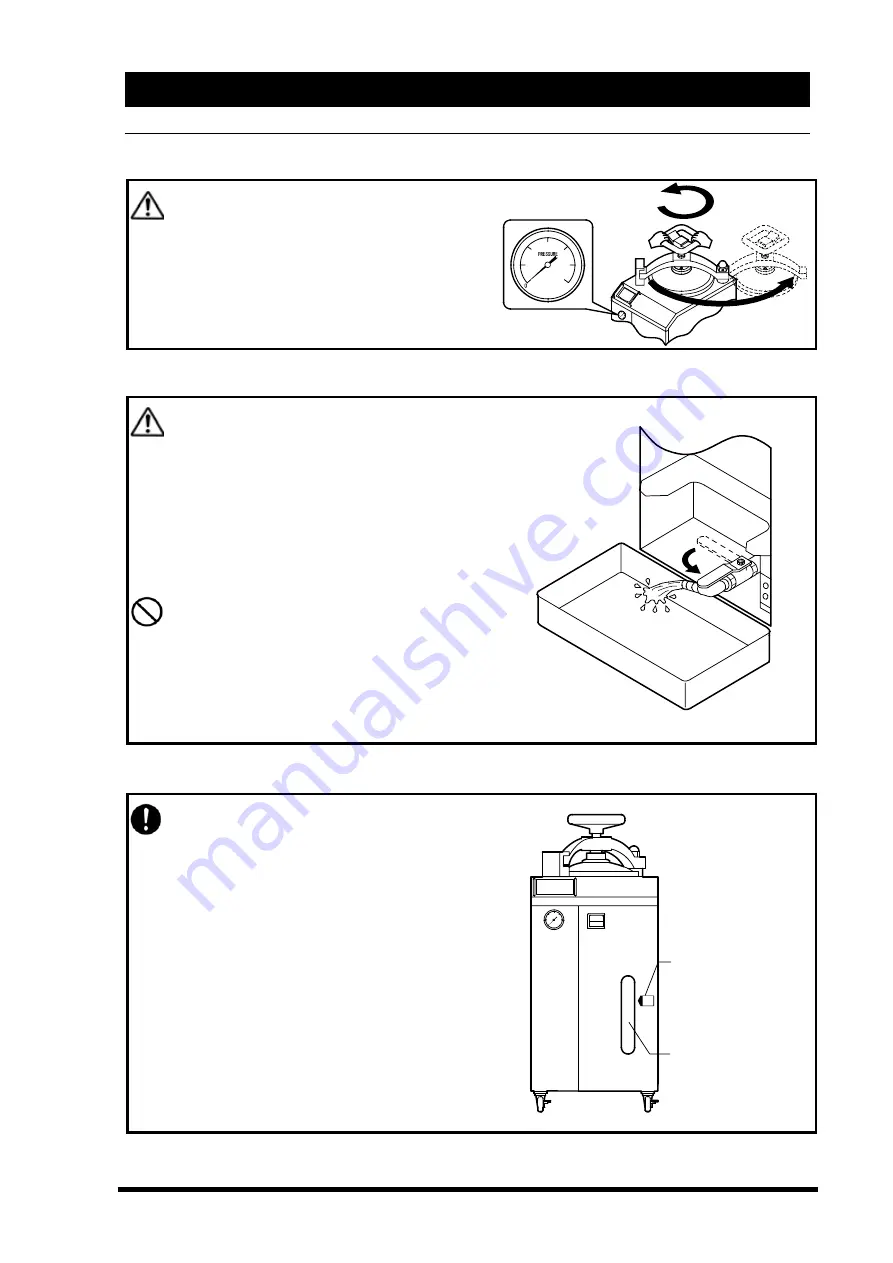

Opening lid

When opening the lid, be sure that the

pressure gauge reads “0psi". Proceed to open

slowly. If the lid is opened at high pressure, hot

steam will spout out.

Drainage

After operation, the water in the chamber is

very hot. Please let the water cool before

draining. Place a drain pan less than 2 inches

in height under the drain valve or connect a

drain hose.

Never drain water during operation. If you

open the drain valve at high pressure, hot

water will spout out.

Water bottle window viewer

Check the water level window. If water level is

close to the upper limit indicated with the caution

label, be sure to drain some water before using.

OPEN

OPEN

Water Bottle

Window Viewer

The upper limit of

water level