1

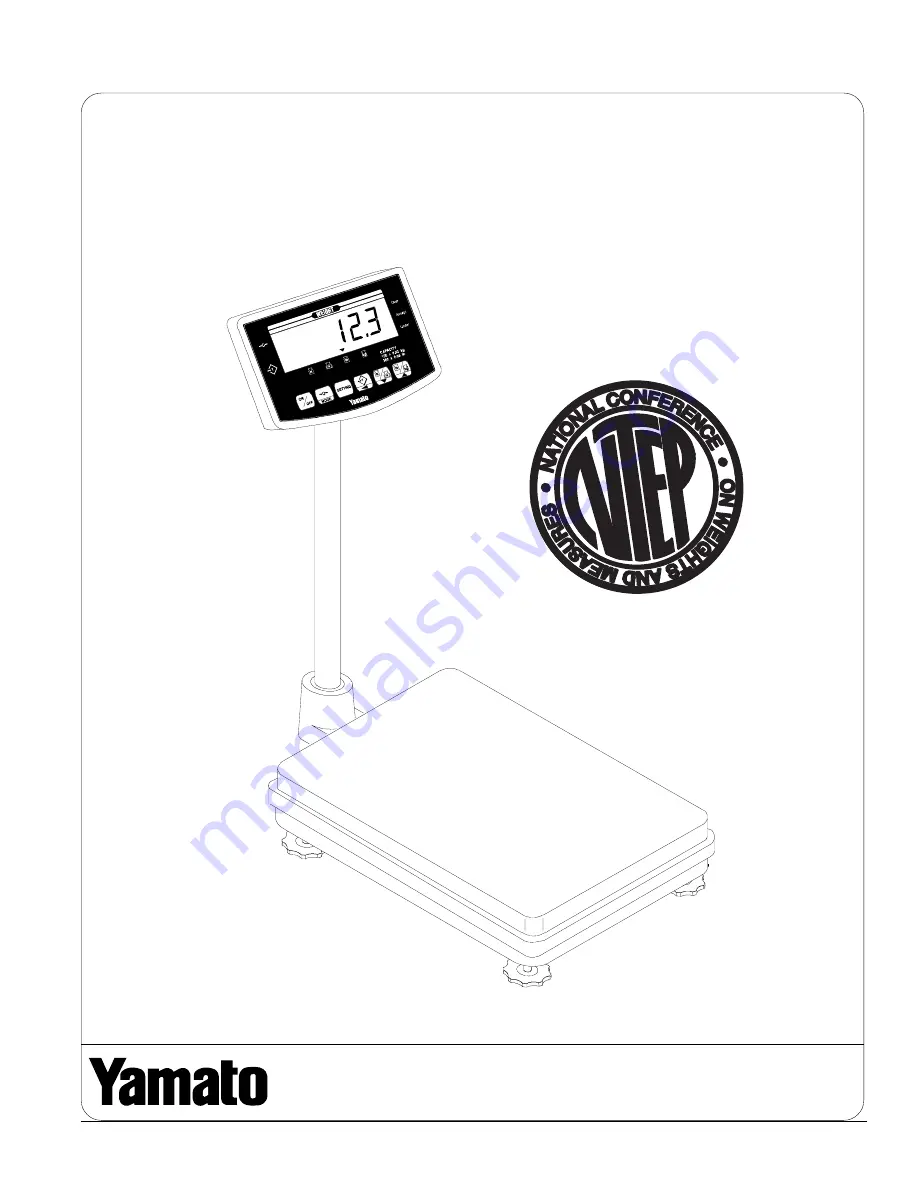

DP-6100 GP

Technical Manual

YAMATO CORPORATION

YAMATO TECH CORPORATION

P.O. Box 15070

#112-19425 Langley By-Pass

Colorado Springs, CO 80935-5070

Surrey, B.C. V3S 6K1

U.S.A.

Canada

Phone (719) 591-1500, Fax (719) 591-1045

Phone (604) 533-2338, Fax (604) 533-0827

MODEL DP-6100GP

Technical Manual