5-26

POWR

E

CYLINDERS

SERVICE POINTS

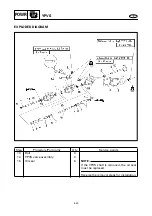

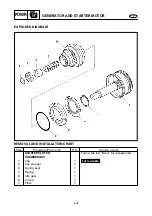

Cylinder inspection

1. Eliminate:

●

Carbon deposits

(with a rounded scraper

1

)

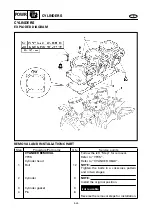

2. Inspect:

●

Cylinder water jacket

Corrosion/mineral deposits

→

Clean

or replace.

●

Cylinder inner surface

Score marks

→

Replace.

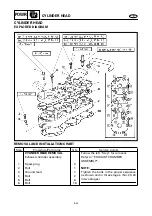

3. Measure:

●

Cylinder bore “D”

(with a cylinder gauge)

Out of specification

→

Replace cylin-

der and piston as a set.

NOTE:

Measure the cylinder bore in parallel and at

a right angle to the crankshaft. Then, aver-

age the measurements.

Standard

Limit

Cylinder

bore “D”

80.000 ~

80.018 mm

(3.1496 ~

3.1503 in)

Original cylinder

bore + 0.04 mm

(0.0016 in)

Taper “T”

—

0.08 mm

(0.003 in)

Out of

round “R”

—

0.05 mm

(0.002 in)

D = Maximum (D

1

~ D

6

)

T = (Maximum D

1

or D

2

) – (Maximum D

5

or D

6

)

R = (Maximum D

1

, D

3

or D

5

) – (Minimum

D

2

, D

4

or D

6

)