–11–

E

INSPECTION AND REPAIR

ENG

NOTE:

BALANCER SHAFT

1. Measure:

S

Oil clearance (balancer shaft bearing)

Out of specification

Replace bearing.

Oil clearance:

0.020

0.048 mm

(0.0008

0.002 in)

Measurement steps:

F

Clean the bearings, balancer shaft and bear-

ing portions of the crankcase.

F

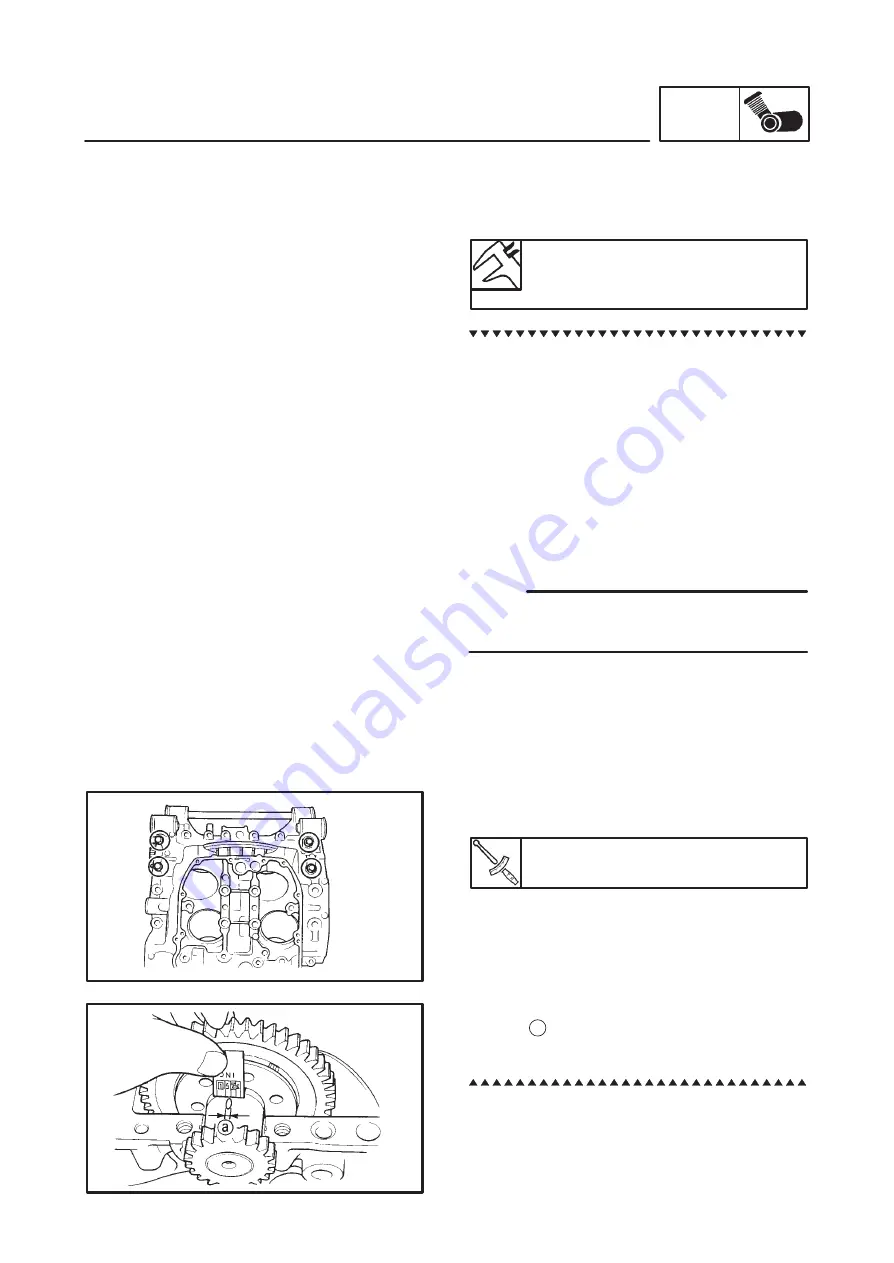

Place the crankcase (upper) on a bench in an

upside down position.

F

Install the upper half of the bearings and the

balancer shaft into the crankcase (upper).

F

Put a piece of Plastigauge

on each balanc-

er shaft journal.

F

Install the lower half of the bearings into the

crankcase (lower) and assemble the crank-

case halves.

Do not move the balancer shaft until the oil

clearance measurement has been completed.

F

Tighten the bolts to specification in the tight-

ening sequence cast on the crankcase.

Bolt (crankcase-M8):

24 Nm (2.4 m

S

kg, 17 ft

S

lb)

F

Remove the crankcase (lower) and lower half

of the bearings.

F

Measure the compressed Plastigauge

width

a

on each balancer shaft journal. If oil

clearance is out of specification, select a re-

placement bearing.