15.

Avoid sudden starts or stops. People can be hurt and

material can be damaged by a lift truck suddenly jumping

into motion and possibly going out of control. Sudden starts

also can damage the lift truck. Sudden stops can cause the

operator to lose a load. Remember, skid marks and dam-

aged equipment are signs of bad driving.

16.

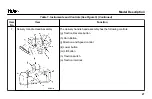

Watch clearances, especially around forks. Watch tail

swing. The operator must be aware that the forks can

sometimes extend beyond the load. This may cause the

operator to hit an object or lift another load.

17.

Look in the direction of travel and keep a clear view of

the path of travel.

18.

Strictly observe the following load handling procedures:

•

Handle only loads within the capacity shown on the

nameplate. This rating represents the maximum load

that should be lifted. However, such factors as weak

floors, uneven terrain, or loads having a high center of

gravity may mean that the safe working load is less than

the rated capacity. When such conditions do exist, the

operator must reduce the load so that the lift truck will

remain stable.

•

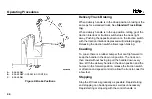

Keep the load against the battery compartment. The bat-

tery compartment acts as a load backrest to help steady

the load.

•

Handle only stable loads. Unstable loads can easily shift

and fall. DO NOT handle loads taller than the load back-

rest unless the load is secured so that no part of it can

shift toward you.

NOTE:

Load backrest extensions are available for this lift

truck as optional equipment.

•

For better visibility and steering, travel or walk with the

forks trailing. When walking, lead the lift truck from either

side of the control handle or delivery handle facing the

direction of travel. When the lift truck must be driven

close to a wall or other obstruction, or into an elevator or

semitruck trailer, travel forks first. On inclines, travel with

the load or forks downhill.

19.

Operate the lift truck only in areas that have been

approved for lift truck operation. Certain areas contain haz-

ardous flammable gasses, liquids, dust, fibers, or other

materials. Lift trucks to be operated in these areas must

have special approval. These areas must be designated to

show the type of approval required for lift truck operation. If

the lift truck has a UL inspection plate, the fire safety

Operating Procedures

39

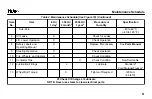

Summary of Contents for MPB045VG

Page 13: ...Figure 4 Warning and Safety Labels Model Description 11...

Page 15: ...Instruments and Controls Figure 5 Instruments and Controls Model Description 13...

Page 50: ...Figure 9 Putting the Lift Truck on Blocks Maintenance Schedule Maintenance Schedule 48...

Page 51: ...Figure 10 Maintenance Points Maintenance Schedule 49...

Page 63: ...1 LED 2 LABEL Figure 14 Charger LED s Maintenance 61...

Page 70: ...Figure 18 Battery Compartment Maintenance 68...

Page 74: ...NOTES 72...