Overhead Guard Replacement

REMOVE

WARNING

DO NOT operate the lift truck without the over-

head guard correctly fastened to the lift truck.

WARNING

DO NOT weld mounts for lights or accessories to

legs of the overhead guard. Changes that are

made by welding, or by drilling holes that are too

big or in the wrong location, can reduce the

strength of the overhead guard.

See your dealer for Yale lift trucks BEFORE per-

forming any changes to the overhead guard.

NOTE:

The lift trucks covered in this YRM are equip-

ped with either a high or low overhead guard. The re-

moval and installation procedures for both types of

overhead guards are the same.

No welding or drilling on legs of overhead guard is

permitted as per previous

NOTE:

The lifting device can be connected to any

number of positions on overhead guard depending

upon lifting device available. The ideal choices are a

four point sling connected to all four corners on top of

overhead guard, or a two point sling connected to two

opposite corners of overhead guard. If a single point

hoist is used, make sure that lift point is in center of

overhead guard. If during initial start of lift, the over-

head guard is off balance, lower immediately and

move hoist to a more centered point.

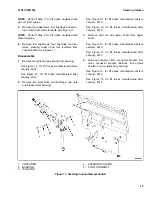

1.

Connect a lifting device to remove overhead

guard. Loosen clamp and disconnect air intake

hose from elbow. Remove bolts, elbow, retainer,

and grommet from overhead guard rear leg. See

Figure 20.

2.

Disconnect wires between frame and overhead

guard. When overhead guard is lifted from frame,

make sure that electrical wires are moved through

holes in overhead guard so that they are not dam-

aged.

3.

The rear legs of overhead guard have two cap-

screws that are located under hood inside engine

compartment, next to radiator. Remove cap-

screws. See Figure 21.

1. CLAMP

2. AIR INTAKE HOSE

3. BOLTS

4. ELBOW

5. RETAINER

6. GROMMET

Figure 20. Disconnect Air Intake Hose

4.

Remove fender cover, dash, and kick panel to re-

move two capscrews on front legs of overhead

guard. See Hood, Seat, and Side Covers Re-

placement for removal procedures.

5.

Using a lifting device, remove overhead guard

from frame and place on floor.

INSTALL

1.

Connect lifting device to top of overhead guard.

Install overhead guard in position on lift truck.

2.

Install two capscrews on front legs of overhead

guard. Tighten capscrews to 66 N•m (49 lbf ft).

See Figure 21.

3.

Install fender cover, dash, and kick panel. See

Hood, Seat, and Side Covers Replacement for in-

stallation procedures.

0100 YRM 1243

Overhead Guard Replacement

25

Summary of Contents for GDP100VX

Page 13: ...Figure 7 Gas Spring Installation 0100 YRM 1243 Hood Seat and Side Covers Replacement 9 ...

Page 40: ...Figure 27 Cummins QSB 3 3L Diesel Engine and Transmission Engine Replacement 0100 YRM 1243 36 ...

Page 52: ...Figure 33 Cummins 4 5L Diesel Engine and Transmission Engine Replacement 0100 YRM 1243 48 ...

Page 57: ...Thank you very much for your reading Please Click Here Then Get More Information ...