12

6.9 AIR MOTOR

Motor

The length of the motor's working life is influenced greatly

by the factors:

a) cleanliness of the air supply

b) lubrication conditions and service

to a) if water and rust can build up inside the air supply system

dirt and water traps must be fitted.

to b) Always use resin and acid free oil (SAE 5W - SAE

10W). Thicker oils clog the vanes and reduce the speed and

power of the hoist. An optimal lubrication extends the working

life of the motor considerably. We highly recommend that

service and oiler units are fitted.

Adjust the oiler so that for every m

3

/min. of air consumed

around 2 - 5 drops of oil are sprayed.

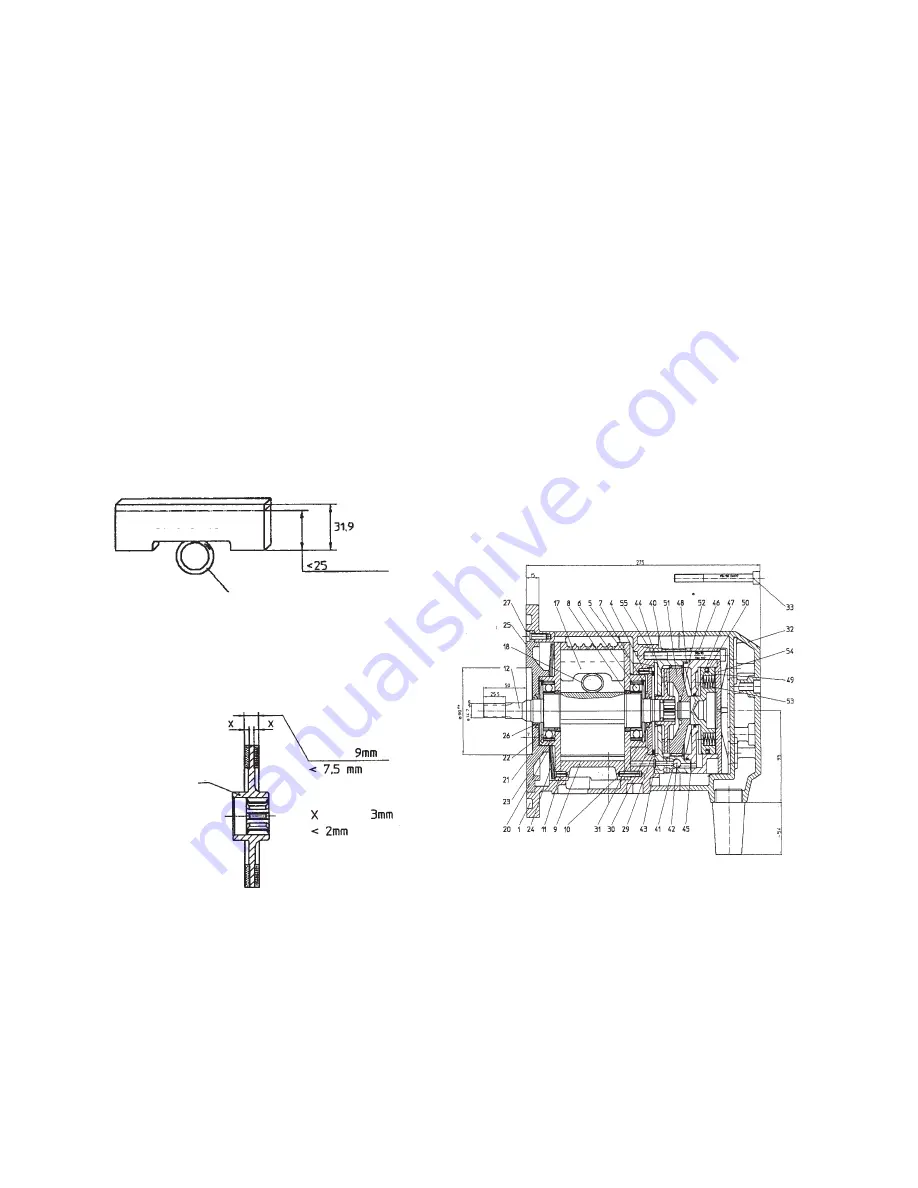

Expendable parts - in particular the vanes - should be

replaced on time. They are worn when their height is less

than 25 mm. We also recommend that the O-Rings (18) that

serve as start-up helps are also be replaced.

One of the main expendable parts are the brake linings (44).

The lining thickness should be controlled at regular intervals

as the wear affects the efficiency of the brake to hold.

The brake disk must be replaced when it's total thickness

becomes less than 7.5 mm or if the brake lining on any side

is less than 2 mm thick.

Disassemble and reassemble the motor

Disassemble - vanes and brake disk

1.) Change vanes (see fig. 20)

Remove the screws (27), end plate (25) and cup spring (24).

With the help of a puller remove the seal plate with bearing

(20) from the rotor. Remove the spacer (23). Remove the

vanes (17) from the rotor slots.

If a puller is not available the complete internal parts can be

removed to be further disassembled on the workbench.

To remove the sealing plates (5) and (20) it can be helpful to

tap the rotor shaft ends on a wooden surface. The motor

cylinder (9) can now be removed and the vanes can be

extracted from the rotor slots. Before replacing new vanes

clean the rotor slots from oil and resin residues. The new

vanes must move freely in the rotor slots (12).

2.) Renew the brake disc

Remove screws (33) and motor end cover (32). Remove

the screws (55).

ATTENTION

: the springs (53) are under

tension. Remove the brake housing cover (54) and springs

(53). Withdraw the air brake housing (46) complete with parts

(47 - 52) from the brake housing (40). Note the O-Ring (45).

Remove the brake disc (44) from the rotor shaft and check

the lining thickness.

Before reassemble clean the brake housing (40) pressure

plate (51) from brake dust.

Coat the rotor shaft end (12, spline) and the inner spline of

the brake disk (44) with an antirust paste (e.g. Altemp Q NB

50) to ensure that the brake disc (44) can move freely on the

rotor (12) spline. Repeat this procedure on the pressure plate

spline (51) and the brake housing (40).

3.) Complete disassembly

Once the motor parts have been removed as described in

1.) and the seal plates (5 and 20) have been removed from

the rotor, the motor cylinder (9) and vanes (17) can been

removed, if required, the bearings (6 and 21) can be removed

from the seal plates (5 and 20) by releasing the circlips (7

and 22). Remove the complete control valve from the motor

body (1). Remove the screws (55) and withdraw the brake

assembly (40 - 54) from the body (1). Remove the O-Ring

(29), seal plate (30) and oil seal (31). Normally the silencer

(2) remains in the body (1) and is only removed if defect.

Original

size

Replace

O-Ring

Brake disk

assy.

Original

Original

Replace

Replace