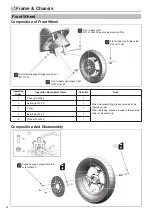

Frame & Chassis

42

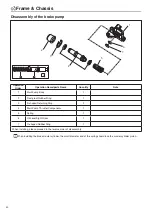

Operation

Order

Operation Name/parts Name

Quantity

Note

1

Brake Pad Guide Pin Bolt

1

2

Brake Pad Dust-proof Cover

1

3

Brake Pad

2

4

Brake Pad Reed

1

5

L/R Pump Body Bolts

2

6

Oil Channel Sealing Ring

2

7

Left Pump Body

1

8

Right Pump Body

1

9

Exhaust Screw

1

10

Piston

2

11

Piston Dust -proof Seal

2

12

Piston Oil Seal

2

When installing, please proceed in the reverse order of disassembly.

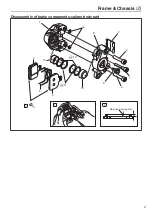

• Before disassembling the caliper, please first discharge the brake fluid in the master cylinder, oil pipe and caliper, and

remove the oil pipe

When disassemble the caliper piston, blow the oil passage hole with compressed air, so that the piston is sent out by air.

Check the wear of the brake pads. If the wear limit is exceeded, replace the front wheel solidity limit. Vertical: 1.0mm

Horizontal: 1.0mm.

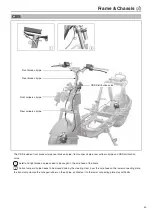

Trouble Check for Brake Failure

Number

Possible cause of failure

Repair method

Note

1

Worn brake pads

Replacement beyond wear limit

2

Worn dist brake

Replacement beyond wear limit

3

Air enters brake fluid

Exhaust air

For the CBS configuration, this

operation requires the use of

special tools (vacuum pump) to

exhaust the air.

4

Insufficient brake fluid

Add brake fluid above the lower limit

5

The main pump thruster fails

Replace the main pump thruster

components (professional person)

Replace the main pump

assembly (professional person)

6

Caliper oil seal failure

Replace oil seal (professional person)

Replace caliper assembly

(professional person)

7

Exhausting air bolts loosen

Fastening bolt

8

Damaged brake oil pipe

Replace oil pipe

9

Oil or butter attached to brake pads

Wash brake pads

After the maintenance and replacement of No. 3, 5, 6, 8 , air release operation is required.

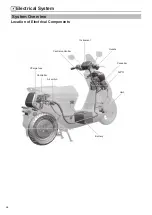

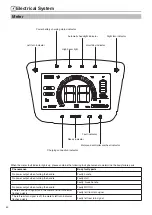

Summary of Contents for C1S

Page 2: ......

Page 14: ...General Information 12 Rear brake oil pipe Motor line Motor line Motor line...

Page 48: ...MEMO...

Page 77: ...Electrical System 75 GPS Front Wall Page 21...

Page 87: ......

Page 88: ...2020 06 29 The first revision...