P 14

da Vinci

Jr. WiFi Pro

CHANGE NOZZLE

CHANGE NOZZLE

Carry out the CHANGE NOZZLE function before changing modules. Once the extruder module has moved to the operating

position, you can

turn off the power

and change the module.

YOU CAN TURN OFF

POWER & CHANGE

NOZZLE NOW

CHANGE NOZZLE

MODULE NOW ?

NO

YES

REPOSITION NOW

PLEASE WAIT

UTILITIES

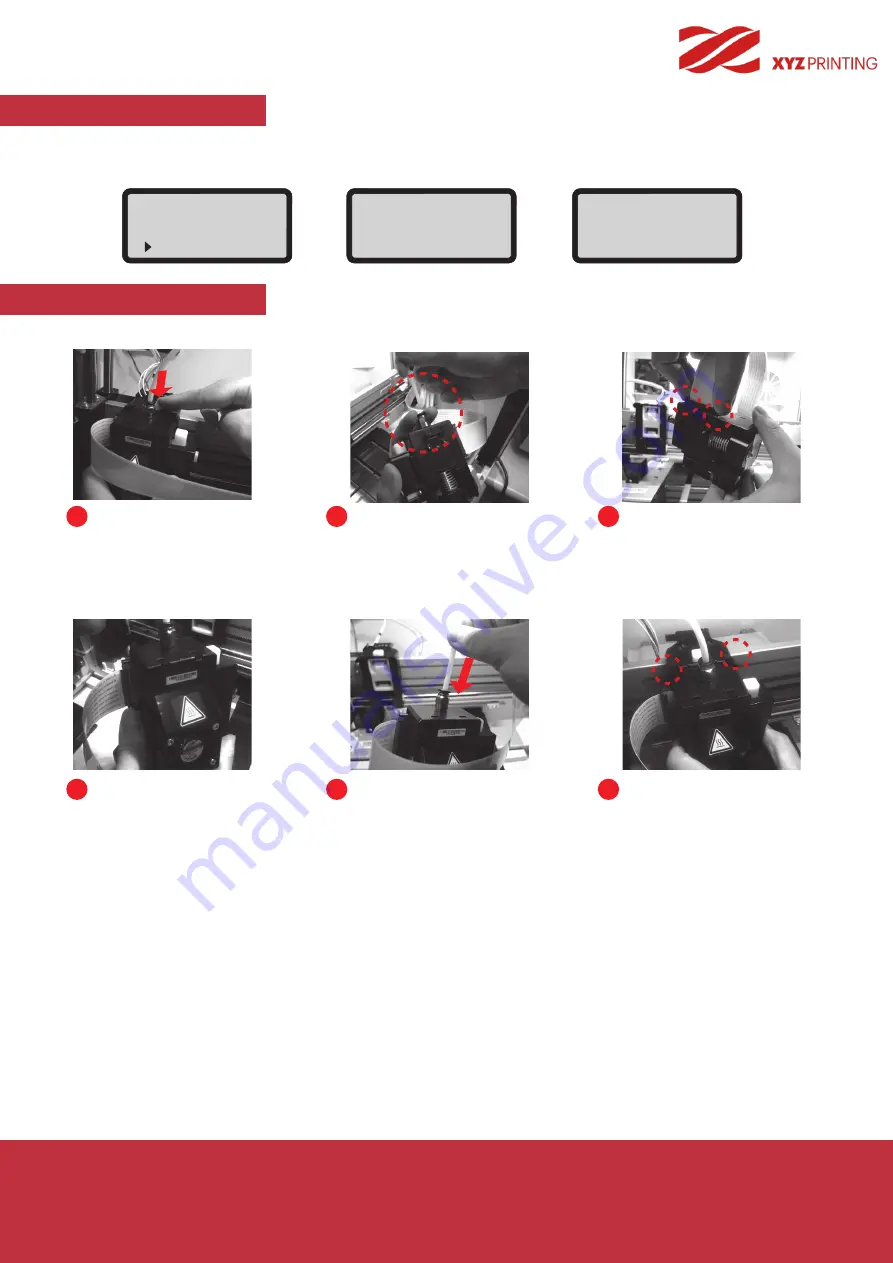

2

5

3

6

Remove the extruder

"Press the white button

at back of the extruder to

release it."

Connect the flat cable to the

new extruder module.

( Be sure to insert the flat cable

in the right direction. )

Lightly press the spring around the

feed hole and remove the filament

guide tube.

Insert the guide tube into the

feed hole all the way down and

install the extruder back to the

printer.

Press the white button and align

the extruder module with the

bracket. Once aligned, release

the white button to connect the

extruder module with the bracket.

Press on the harness chips

and disconnect the cable.

Exchange the extruder module

Install the filament guide

tube to the extruder module

Install the extruder

1

4