Ver.1

April 2016

P 20

da Vinci

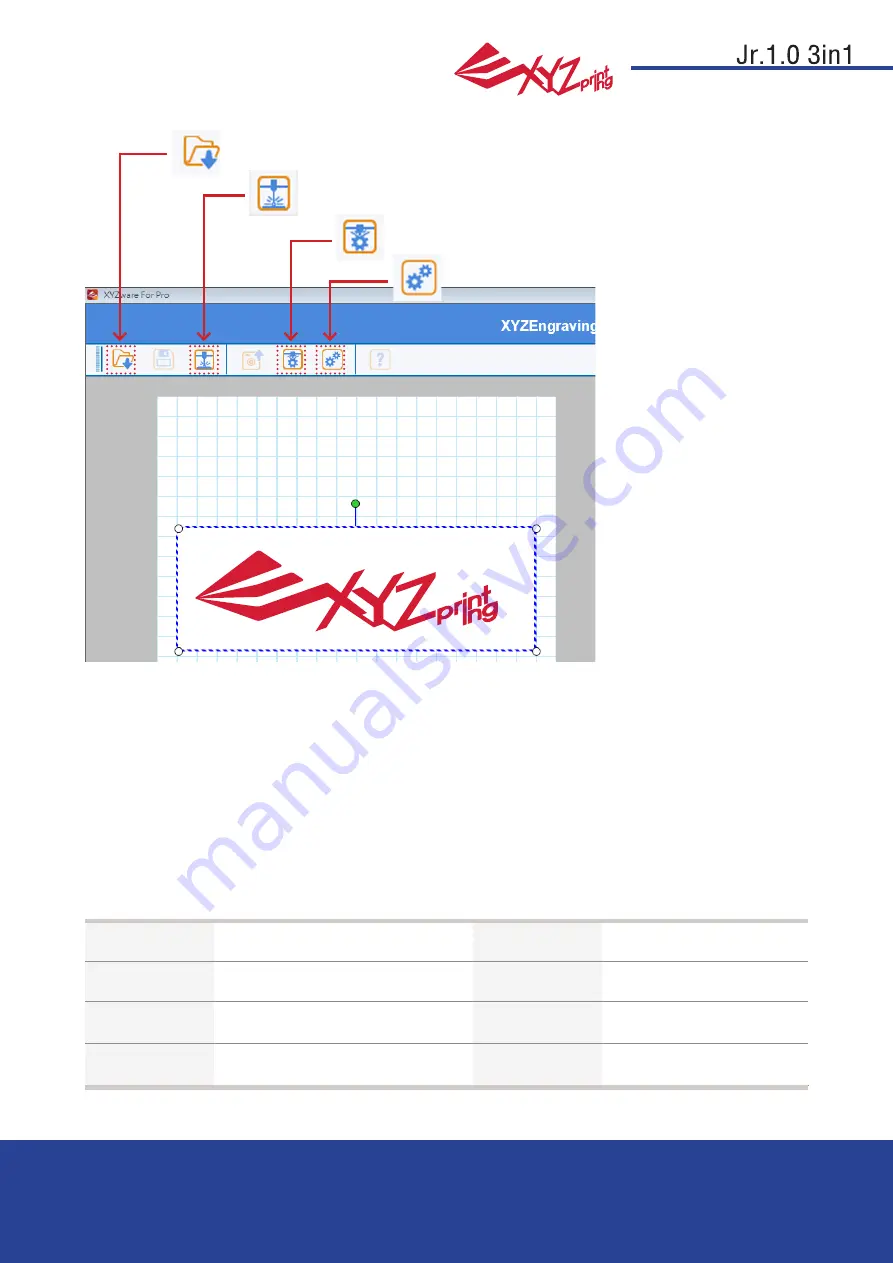

Once basic editing has been completed, select this "Engrave" icon.

Select “Import” on the device to select the graphic file you wish to engrave.

Alternatively, select this "Advanced Engraving Settings" icon to

complete advanced settings before engraving.

Function Description

:

Select "Edit". The software screen shall display the laser engraver settings.

For more details on laser engraving settings and methods,

please refer to the "Laser Engraving Module User Manual".

Pause and cancel the laser sculpting

●

●

●

"Language" and "Automatic Feedback" (feedback laser

engraving settings) settings.

The user may choose between Vector / Pixel engraving modes (default software setting is

Vector mode).

Set engraving speed, number of engraving layers, contour detection sensitivity, or color depth

detection sensitivity.

PAUSE:Select “PAUSE” to pause the laser engraving process.

RESUME:To cancel the pause and resume the printing, select “RESUME”.A screen will appear to confi rm whether

to resume the engraving process. Select “YES” to continue the laser engraving process.

CANCEL: To cancel the laser engraving job, select “CANCEL”. A screen will appear to confirm

whether to cancel the engraving process. Select “YES” to cancel the laser engraving process.

Laser Specification

●

Laser

Wavelength

450nm+5nm/-10nm InGaN

Laser Power

350mW ± 10%

Laser Power for

Classifi cation

Class 3B

Beam Diameter

≦

1mm

Engraving area

15 x 15 cm / 5.9" x 5.9"

File Types JPG / PNG / GIF / BMP

Mode of

Operation

CW (Continuous Wave)

SELECT MODULE