User Manual da Vinci 2.0 Duo

P 20

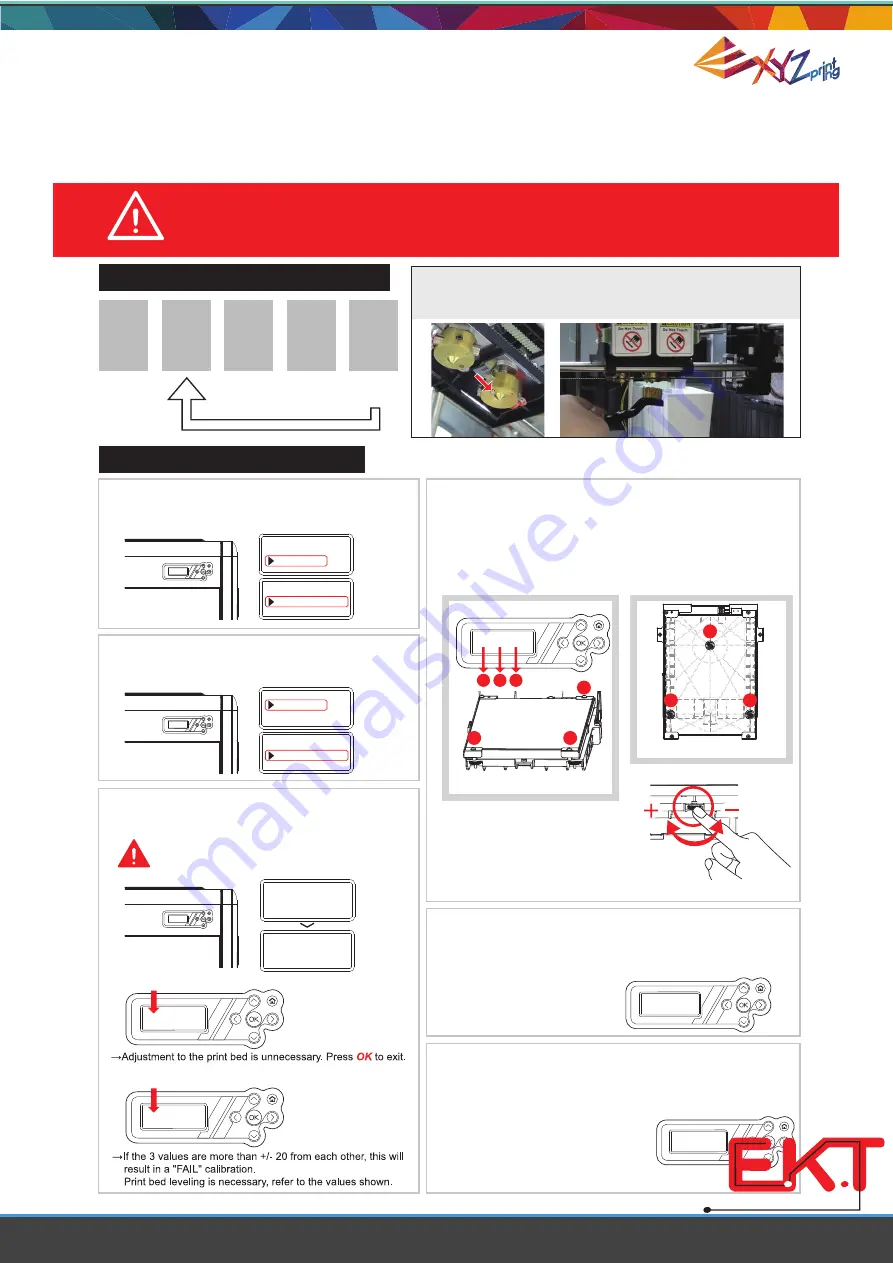

5-5 Print Bed Adjustment Instructions

2.

1. 4.

UTILITIES

SETTINGS

INFO

DA VINCI 2

.

0 DUO

DA VINCI 2

.

0 DUO

SYSTEM VERSION

INFO

CARTRIDGE STATS

STATISTICS

UTILITIES

SETTINGS

INFO

CALIBRATE

BUILD SAMPLE

uTILITIES

jOG MODE

3.

CALIBRATE

IN PROGRESS

PLEASE WAIT

EXTRUDER HEATING

TEMPERATURE999

¢X

C

PLEASE WAIT

(Adjust the location of the screws)

5.

1

3

2

1

A

B

C

2

3

This print bed has been factory calibrated before shipping. Recalibration

is necessary if there are print issues when starting to print or the nozzle

gets too close to the print bed. When in doubt, it is recommended to con-

tact service center for more information.

Print bed adjustment flow chart

Perform again!

Step

1

2

3

4

5

Step

Step

Step

Step

Print bed adjustment steps

Click INFO>SYSTEM VERSION using the

function keys to make sure your firmware is the

latest.

Click UTILITIES>CALIBRATE using the

function keys and select Yes to perform

print bed measurement.

The printer starts automatic measurement. Wait

for 2~3 minutes and verify the data shown.

Note: During the measurement process, the

print bed and print module will be heated.

Care should be taken during operation!

I. If

SUCCESS

is shown.

II. If

FAIL

is shown.

Tip II. View the printer from the front

when making adjustment

Use small dial turns to approximate the desired value

Rotate the screw to the

left

to

raise the bed (value increases)

Rotate the screw to the

right

to

lower the bed (value decreases)

Refer to the values for adjustment:

After adjusting the screw(s), please run "Calibrate"

(see step 2). If the screen repeats "FAIL", please

continue the steps for calibration. Until "

SUCCESS

" is

shown on screen, press "OK" to complete the calibra-

tion.

If the value shown is always

ERR

,

ERR

,

ERR

,

follow the steps below to clean.

¡

Reminder

A. Clean the surface of the print head using

the copper brush.

(Clean the contact point between the print head

and print bed)

B. Wipe and clean the measurement

points as shown on the print bed in step 4

C. Perform the calibration process again.

Note: 3 values shown on screen indicate the distance between

the detect pin by the nozzle and the edge of the print bed. If

any value is out of the range of 90 to 110, please adjust the

value by turning the screw(s) under the print bed.

Tip I. Value set and corresponding thumbscrew:

(Location of the measurement points)

To clean the molted filament from nozzle thoroughly, it is

recommended to activate CLEAN NOZZLE function to

keep heating the extruders for better cleaning.

1

3

2

CALIBRATE

fail

+

245

,+

305

,+

315

[

OK

]

TO RETURN

CALIBRATE

SUCCESS

100

+

100

, +

100

,

+

100

[

OK

]

TO SAVE

CALIBRATE

SUCCESS 100

+

100

, +

100

,

+

100

[

OK

]

TO SAVE

CALIBRATE

fail

+

245

,+

305

,+

315

[

OK

]

TO RETURN

CALIBRATE

fail

ERR,ERR,ERR

[

OK

]

TO RETURN

w w w . e k t

2

. c o m

Electronics

Katrangi

Trading