10

T.I.R., while a satisfactory angular

misalignment is .004" T.I.R. per inch of

radius R. See Figure 8.

Final Alignment

Final alignment cannot be accomplished until

the pump has been operated initially for a

sufficient length of time to attain operating

temperature. When normal operating

temperature has been attained, secure the

pump to re-check alignment and compensate

for temperature accordingly. See the section

entitled Alignment Procedure.

WARNING: Rotating Components

Hazard

Do not operate pump without all guards in

place.

Failure to follow these instructions could

result in serious personal injury or death, or

property damage.

OPTIONAL Alignment Procedure

If desired, the pump and motor feet can be

doweled to the base after final alignment is

complete. This should not be done until the

unit has been run for a sufficient length of

time and alignment is within the tolerance.

See the section entitled Doweling.

CAUTION: Extreme Temperature

and/or Flying Debris Hazard

Eye protection and gloves required.

Failure to follow these instructions could

result in property damage and/or moderate

personal injury.

NOTE:

Pump may have been doweled to base at

factory.

DOWELING

Dowel the pump and driving unit as follows:

a. Drill holes through diagonally opposite feet

and into the base. Holes must be of a

diameter 1/64 inch less than the diameter of

the dowel pins. Clean out the chips.

b. Ream the holes in feet and base to the proper

diameter for the pins (light push fit). Clean out

the chips.

c. Insert pins to be approximately flush with feet.

SUCTION AND DISCHARGE PIPING

When installing the pump piping, be sure to

observe the following precautions:

Piping should always be run to the pump.

Do not move pump to pipe. This could make final

alignment impossible.

Both the suction and discharge piping should be

supported independently near the pump and

properly aligned, so that no strain is transmitted to

the pump when the flange bolts are tightened. Use

pipe hangers or other supports at necessary

intervals to provide support. When expansion

joints are used in the piping system, they must be

installed beyond the piping supports closest to the

pump. Tie bolts should be used with expansion

joints to prevent pipe strain. Do not install

expansion joints next to the pump or in any way

that would cause a strain on the pump resulting

from system pressure changes. It is usually

advisable to increase the size of both suction and

discharge pipes at the pump connections to

decrease the loss of head from friction.

Install piping as straight as possible, avoiding

unnecessary bends. Where necessary, use 45-

degree or long sweep 90-degree fitting to

decrease friction losses.

Make sure that all piping joints are air-tight.

Where flanged joints are used, assure that inside

diameters match properly.

Remove burrs and sharp edges when making up

joints.

Do not “spring” piping when making any

connections.

Provide for pipe expansion when hot fluids are to

be pumped.

Suction Piping

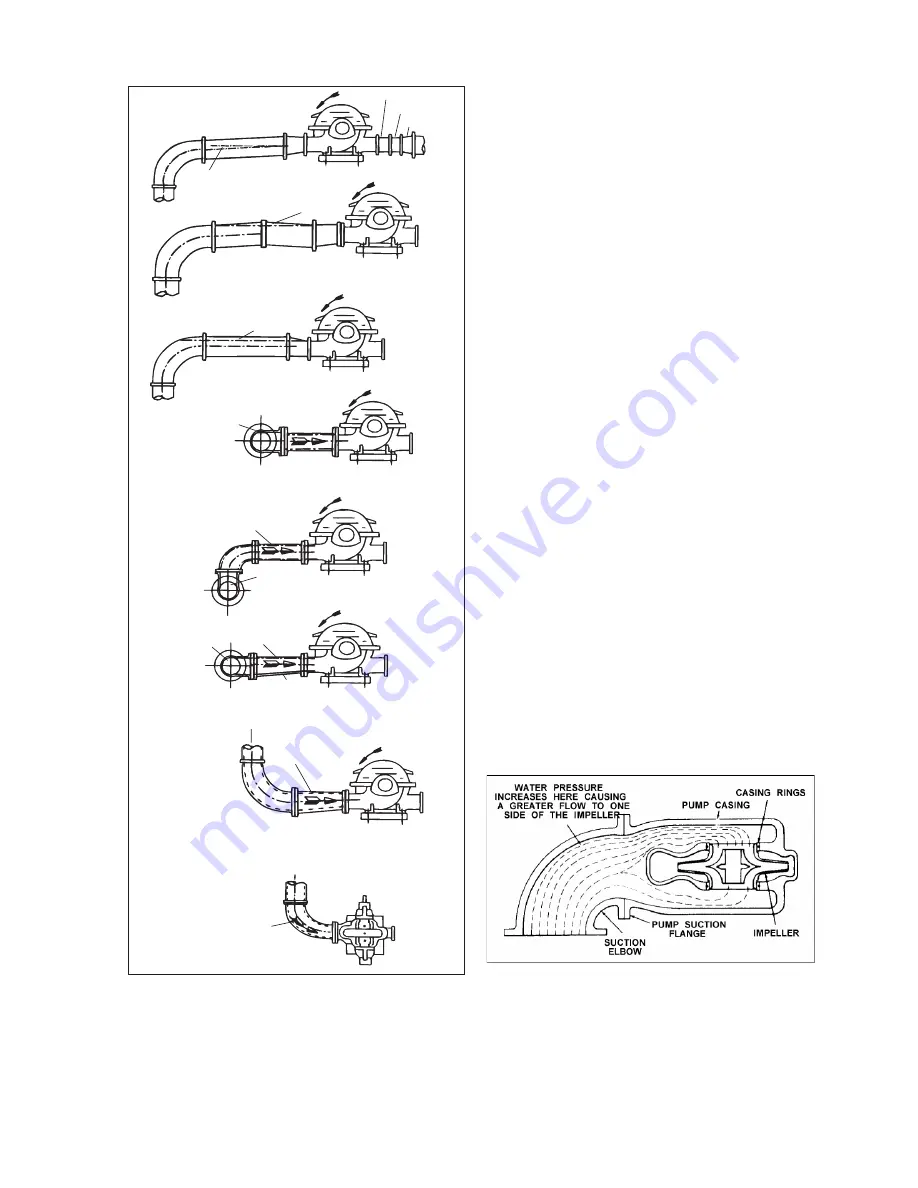

When installing the suction piping, observe

the following precautions. See Figure 9.

The sizing and installation of the suction

piping is extremely important. It must be

selected and installed so that pressure losses

are minimized and sufficient liquid will flow

into the pump when started and operated.

Many NPSH (Net Positive Suction Head)

problems can be attributed directly to

improper suction piping systems.

11

CHECK VALVE

GATE VALVE

INCREASER

CORRECT

C OF PIPE

SUCTION PIPE INSTALLED WITH

A GRADUAL RISE TO PUMP

L

LEVEL

AIR POCKET

INCORRECT

AIR POCKET

INCORRECT

AIR POCKET

INCORRECT

GRADUAL RISE

TO PUMP

NO AIR

POCKETS

CORRECT

NO AIR

POCKETS

GRADUAL RISE

TO PUMP

ECCENTRIC

REDUCER

CORRECT

DISTANCE PLUS

ECCENTRIC REDUCER

STRAIGHTENS FLOW

CORRECT

PATH OF

WATER

INCORRECT

Figure 9: Suction Pipe Installations

(Piping supports not shown)

Friction losses caused by undersized suction

piping can increase the fluid’s velocity into the

pump. As recommended by the Hydraulic

Institute, Standard ANSI/HI 1.1-1.5-1994,

suction pipe velocity should not exceed the

velocity in the pump suction nozzle. In some

situations pipe velocity may need to be

further reduced to satisfy pump NPSH

requirements and to control suction line

losses. Pipe friction can be reduced by using

pipes that are one to two sizes larger than the

pump suction nozzle in order to maintain pipe

velocities less than 5 feet/second.

Suction piping should be short in length, as direct

as possible, and never smaller in diameter than

the pump suction opening. If the suction pipe is

short, the pipe diameter can be the same size as

the suction opening. If longer suction pipe is

required, pipes should be one or two sizes larger

than the opening, depending on piping length.

Suction piping for horizontal double suction pumps

should not be installed with an elbow close to the

suction flange of the pump, except when the

suction elbow is in the vertical plane. A suction

pipe of the same size as the suction nozzle,

approaching at any angle other than straight up or

straight down, must have the elbow located 10

pipe diameters from the suction flange of the

pump. Vertical mounted pumps and other space

limitations require special piping.

There is always an uneven turbulent flow around

an elbow. When it is in a position other than the

vertical it causes more liquid to enter one side of

the impeller than the other. See Figure 10. This

results in high unequalized thrust loads that will

overheat the bearings and cause rapid wear, in

addition to affecting hydraulic performance.

Figure 10: Unbalanced loading of a double

suction impeller due to uneven flow

around an elbow adjacent to the pump