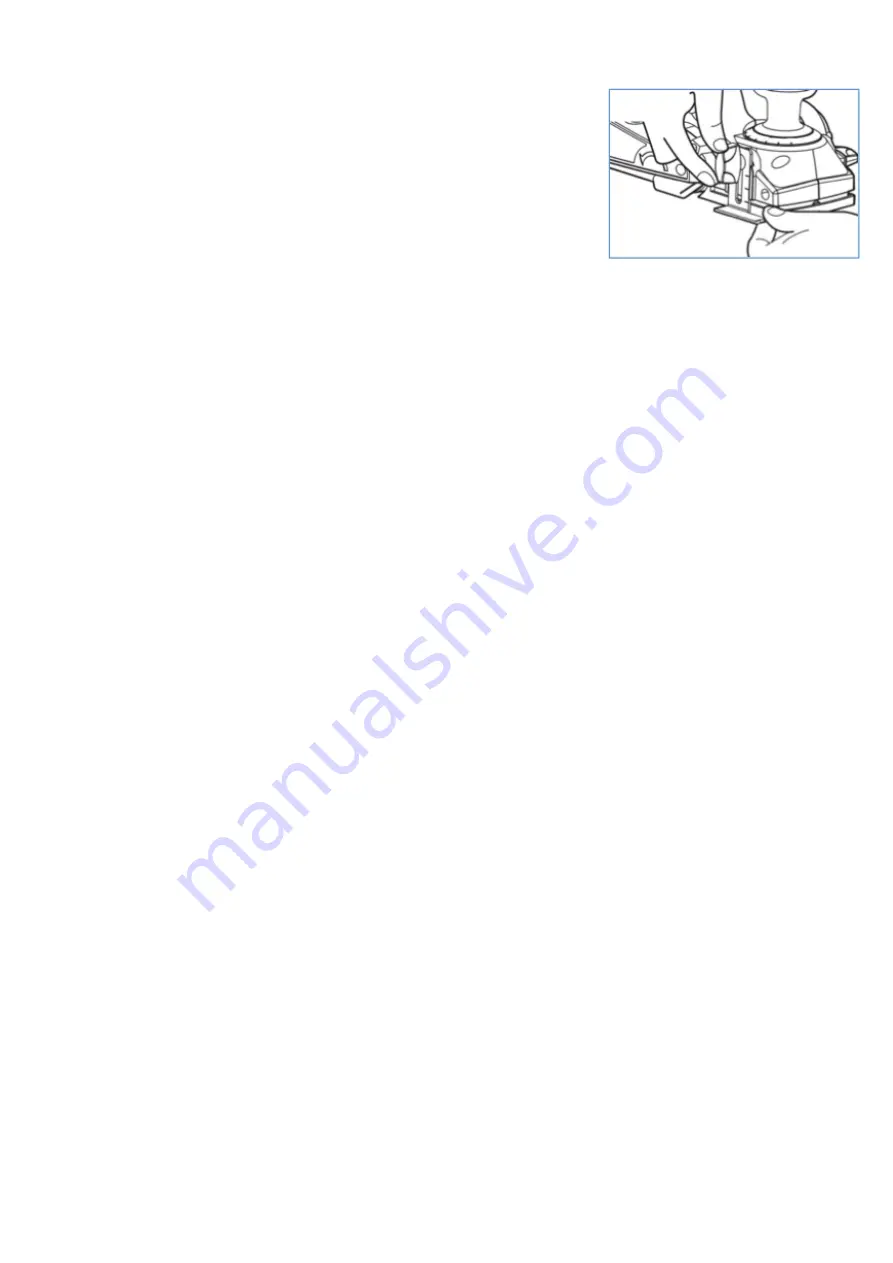

RABBETING DEPTH GAUGE

CAUTION: Always ensure that the tool is switched off and unplugged

from the power supply before adjusting or installing the rabbeting

depth gauge. Wait until the blades have come to a complete stop

before making any adjustments.

1.

Disconnect the planer from the power source.

2.

Attach the rabbeting depth gauge to the right-hand side of the

planer using the depth gauge knob.

3.

Loosen the knob, position the depth gauge to the desired

rabbeting depth, and then retighten the knob

When the depth gauge touches the unplaned section of the workpiece

to the right-hand side of the tool, the rabbeting is to the required depth.

NOTICE: The rabbeting depth gauge allows only approximate depth

setting. If it is necessary to rabbet to a precise depth, plane a scrap

piece of wood, measure the rabbeted depth, and adjust the setting as

necessary.

MAINTENANCE

SERVICE: Preventive maintenance performed by unauthorized personnel may result in misplacing of

internal wires and components, possibly causing a serious hazard. We recommend that all tool service be

performed by a WEN Service Center or Authorized WEN Service Station.

TOOL LUBRICATION: Your tool has been properly lubricated and is ready to use. It is recommended that

tools with gears be regreased with a special gear lubricant at every brush change.

CARBON BRUSHES: The brushes in your tool have been engineered for many hours of dependable service.

To maintain peak efficiency of the motor, we recommend examining the brushes every two to six months.

Only genuine WEN replacement brushes designed specifically for your tool should be used.

BEARINGS: Bearings that become noisy (due to heavy load or abrasive material cutting) should be replaced

as soon as possible to avoid overheating or motor failure.

CLEANING: Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not

at-tempt to clean these components by inserting pointed objects through openings.

WARNING: To avoid accidents, always disconnect the tool from the power supply before cleaning or

performing any maintenance. The tool may be cleaned most effectively with compressed dry air. Always

wear safety goggles when cleaning tools with compressed air.

WARNING: Certain cleaning agents and solvents damage plastic parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain am-monia.

Summary of Contents for XT106372

Page 12: ......