https://www.XPOtool.com

Item 60910

Page 9

The Tool Experts

04 2022-1

6

th

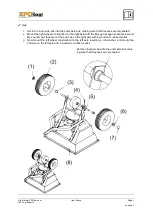

step: adjustments

After having finished the above-mentioned steps, the following steps do not need to be followed. They

are necessary in case the individual parts do not properly match. To operate this spreader, push the

handle up. You can shift the position of the wing nut on the pressure gauge and lever to adjust the

spacer of the three holes between the hopper and adjustable plate according to your needs.

Set the steel wire into the small

hole.

To operate this spreader, push the handle all

the way up to the highest position.

Push the handle

alle the way down.

Use it to adjust the

adjustable plate so

that the hole on the

hopper bottom ex-

actly matches the

holes on the adjust-

able plate.

Untighten and re-

move both bolts.

Re-insert them af-

ter modifying the

adjustments.

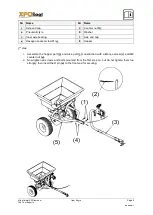

The drive wheel should turn in

the direction shown while the

spreader in pushed forward.