Introduction

2-1

Manual 0-4809

SECTION 2:

INTRODUCTION

2.01 Overview

Plasma is a gas which has been heated to an extremely

high temperature and ionized so that it becomes elec-

trically conductive. The plasma arc cutting process uses

this plasma to transfer an electrical arc to the work-

piece. The metal to be cut is melted by the heat of the

arc and then blown away.

2.02 General Specifications

System Descriptions

NXP35

Maximum Output

35 Amps

Input Voltage & Phase

230V,

Single Phase

Frequency

50/60Hz

Input Power

7.4 kVA

Current Input Fuse

20 Amps

No Load Voltage

330V

Load Voltage

94V

Output Current

15-35 Amps

Post Flow Time

10 Seconds

Operating Air Pressure

75 psi (5.2 bar)

Maximum Air Pressure

125 psi (8.6 bar)

Air Flow

400 scfh

6.6 scfm

(188.7 lpm)

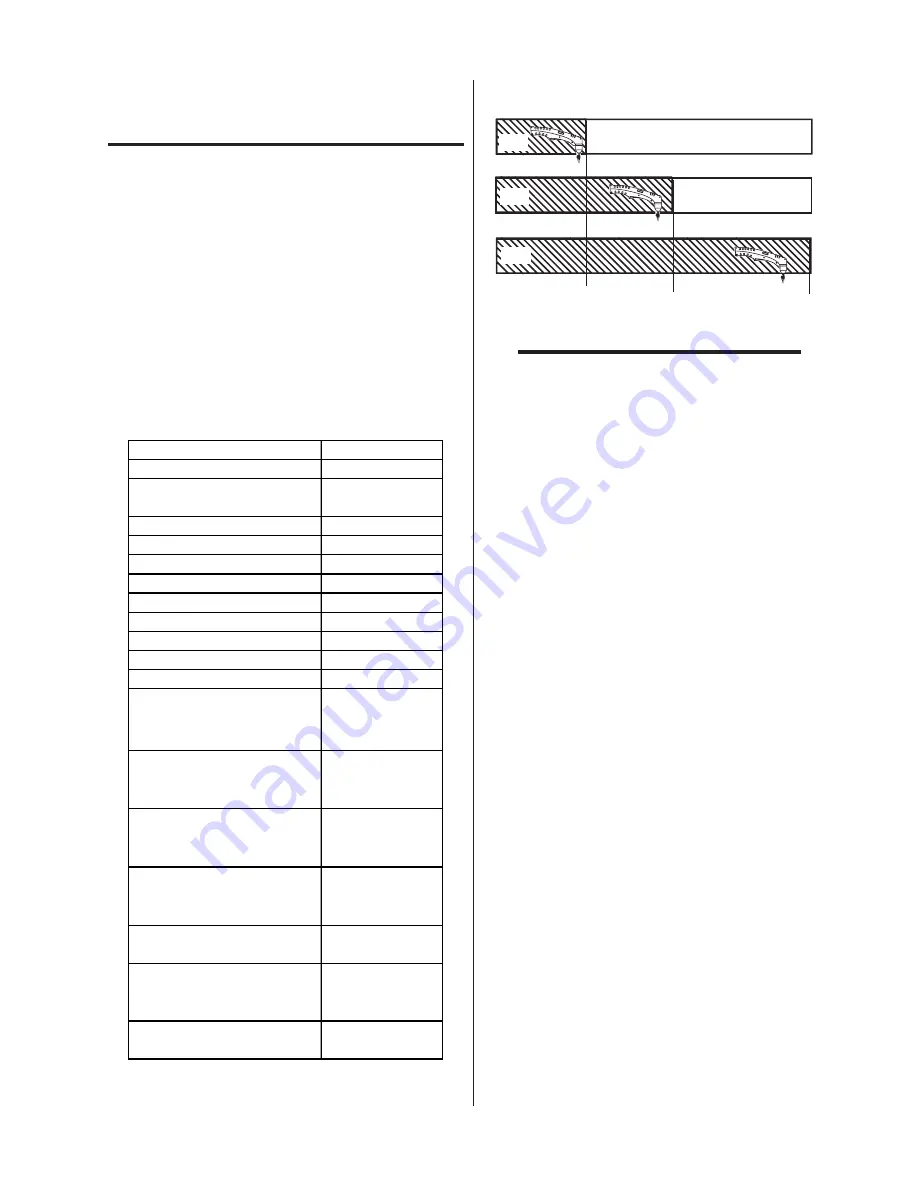

System *Duty Cycle ratings

at Ambient Air Temperatures

of 40° C / 104° F.

35% @ 35Amps

System *Duty Cycle ratings

at Ambient Air Temperatures

of 40° C / 104° F.

60% @ 27Amps

System *Duty Cycle ratings

at Ambient Air Temperatures

of 40° C / 104° F.

100% @ 20Amps

Maximum Cutting Capacity

@ 35A

1/2" (12mm)

Dimension (W x D x H)

8.3"x20"x14.8"

(210 mm x 510

mm x 350 mm )

Net Weight

44 lbs.

(20kg )

20A

27A

35A

35% (3.5 min)

60% (6 min)

100% (10 min)

OFF

OFF

CUT

CUT

CUT

Ar

t # A-0450

5

NOTE:

*Duty Cycle is the percentage of time the sys-

tem can be operated without overheating. Duty

cycle is reduced if primary input voltage (AC) is

low or the DC voltage is higher than shown in

previous chart.

2.03 Features

• PORTABLE - Weighing just 44 lbs., (20 kg) it is

easily moved from location to location.

• POWERFUL CUTTING PERFORMANCE

-

Maximum cutting capacity is 1/2” (12mm).

• CUTS MOST METALS - Useful for most metals

such as stainless steel, aluminum, mild steel, cop-

per and alloys.

• NO HIGH FREQUENCY - Starts without high-

frequency so it won’t interfere with controls or

computers.

• MORE TORCH, LESS MONEY - The SL60™

1Torch™ provides state of the art technology and

performance of more expensive torches.

Summary of Contents for NXP35

Page 2: ......