12

O-ring is less than the piston O.D., please replace the O-ring to get proper

performance.(Please contact with our authorized dealer to purchase, the part No 56).

5. Fill the grease into the aluminum head, please make sure cleaned inside before filling.

a) Recommend the grease from manufacturer site, there is a tube of 60g grease included

the case. (Please contact with our authorized dealer to purchase, the part No 108).

Notice

:

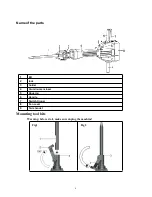

There are 4 grooves in the aluminum head, Please fill the grease in all these 4 grooves by

15g in each, and total 60g grease. (See Fig 5 and Fig 6)

6. Fill the 15 g oil in the cylinder; please make sure it is clean before filling. (See Fig 7)

7. Assemble back(See Fig 8)

a) Assemble the piston into cylinder, please make sure if the O-ring has been assembled.

b) Assemble the cylinder into aluminum head.

c) Tighten the 4 inner HEX head screws; be careful of no missing spring washer. If tighten

the screws by electrical or pneumatic driver, please check the torque of screw by 12mm

wrench to make sure tightening properly.

d) If the conditional, can put glue on the screw and then screw in(repeat the step above C)

*Suggestion: All above operations to be carried out by our authorized service agent.

Maintenance and inspection

Before do any maintenance, ensure unplug the plug.

1. Inspecting the demolition hammer

Use a dull accessory, such as bull point, cutter, etc., will cause motor malfunction and

efficiency degraded. Replace with a new one when your accessory is abased.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that they are properly tightened. Any loose

should be tighten immediately, failure to do maybe cause serious hazard.

3. Inspecting the bit retainer

The retainer may become loose due to excessive use. Make sure the bit shank position is

hold securely, if any wear or damage is found, ask the authorized service people to maintenance.

4. Maintenance the motor

The motor is the heart of the machine, please avoid any damage to the winding, or any water

and oil to wet it.

5.

Carbon brush replacements

Carbon brush are consumable parts, when it becomes worn or "limit worn" it can cause motor trouble, we

use auto-stop carbon brush, it stoped automatically when carbon brush worn out, at that time, replace a

new couple of them as follwing procedure: