Application

This hammer should be applied to breaking concrete, chipping off concrete, grooving, bar cutting,

and driving piles in installation of piping and wiring, unitary facility installation, machinery installation

water supply, and drainage work, interior jobs, harbor facilities and other civil engineering work etc..

Contents

1. Machine information

2. Safety instruction

3. Assembly

4. Operation

5. Maintenance

6. Warranty

7. Environment

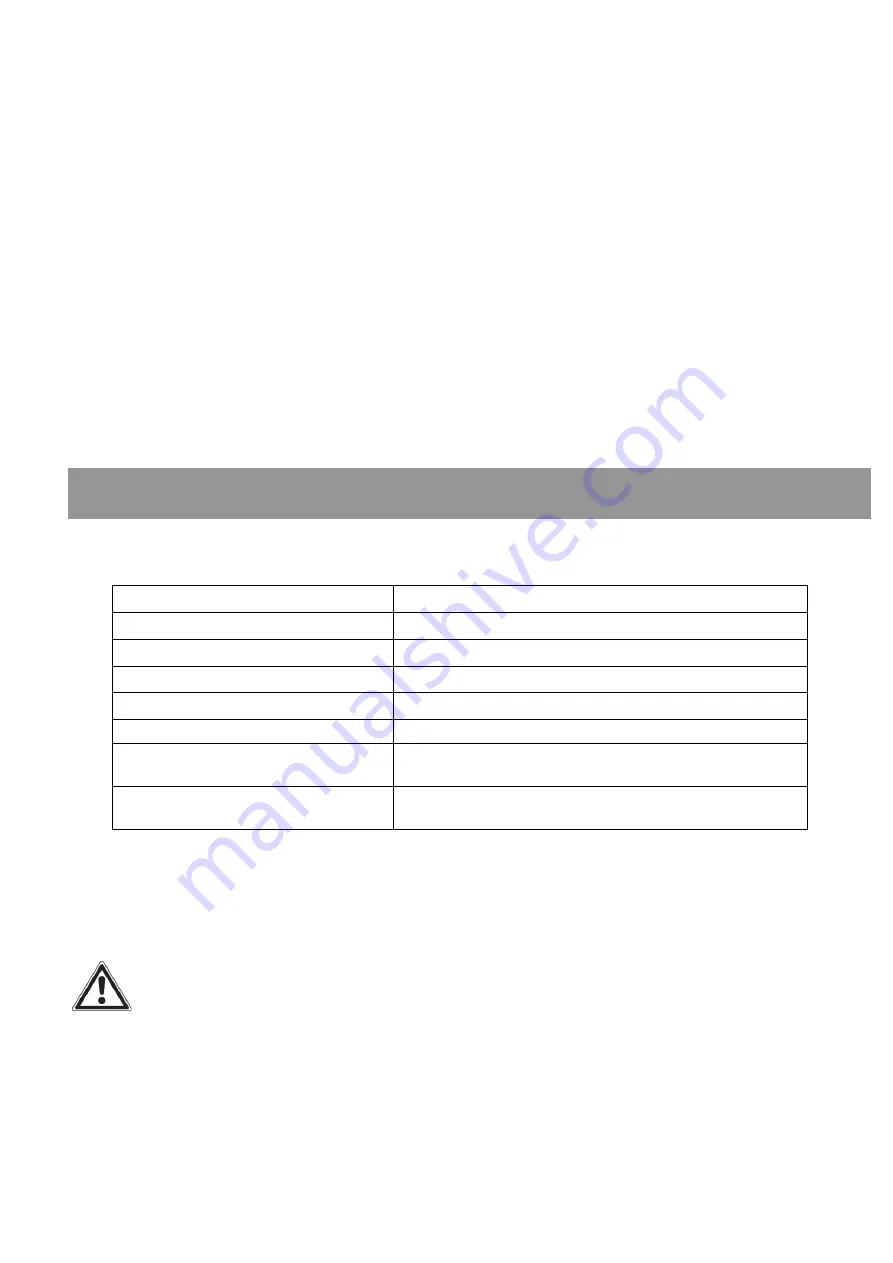

Technical specifications

Machine Type

XP-G90A

Voltage AC

220-240V

Frequency 50Hz

Input power

2200W

Impact rate

950 min-1

Weight 30kg

Sound pressure values (in

accordance with 2000/14/EC)

105.38dB(A)

Guaranteed Sound power values

(in accordance with 2000/14/EC)

110dB(A)

Note: Noise and vibration values are determined acc. to EN 60745-1 and EN 60745-2-6.

Note: The declared vibration value has been measured in accordance with a standard test method and

may be used for comparing one power tool with another.

The declared vibration value may also be used to evaluate the exposure for the user caused by vibration

in advance.

Warning! Depending on the actual use of the power tool the vibration values can differ from

the declared total.

Adopt proper measures to protect yourself against vibration exposures. Take the whole work

process including times the power tool is running under no load or switched off into

consideration.

Proper measures include among others regular maintenance and care of the power tool and

application tools, keeping hands warm, periodical breaks and proper planning of work

processes.

1. Machine information