Troubleshooting

212

WorkCentre 7500 Series Multifunction Printer

User

Guide

8.

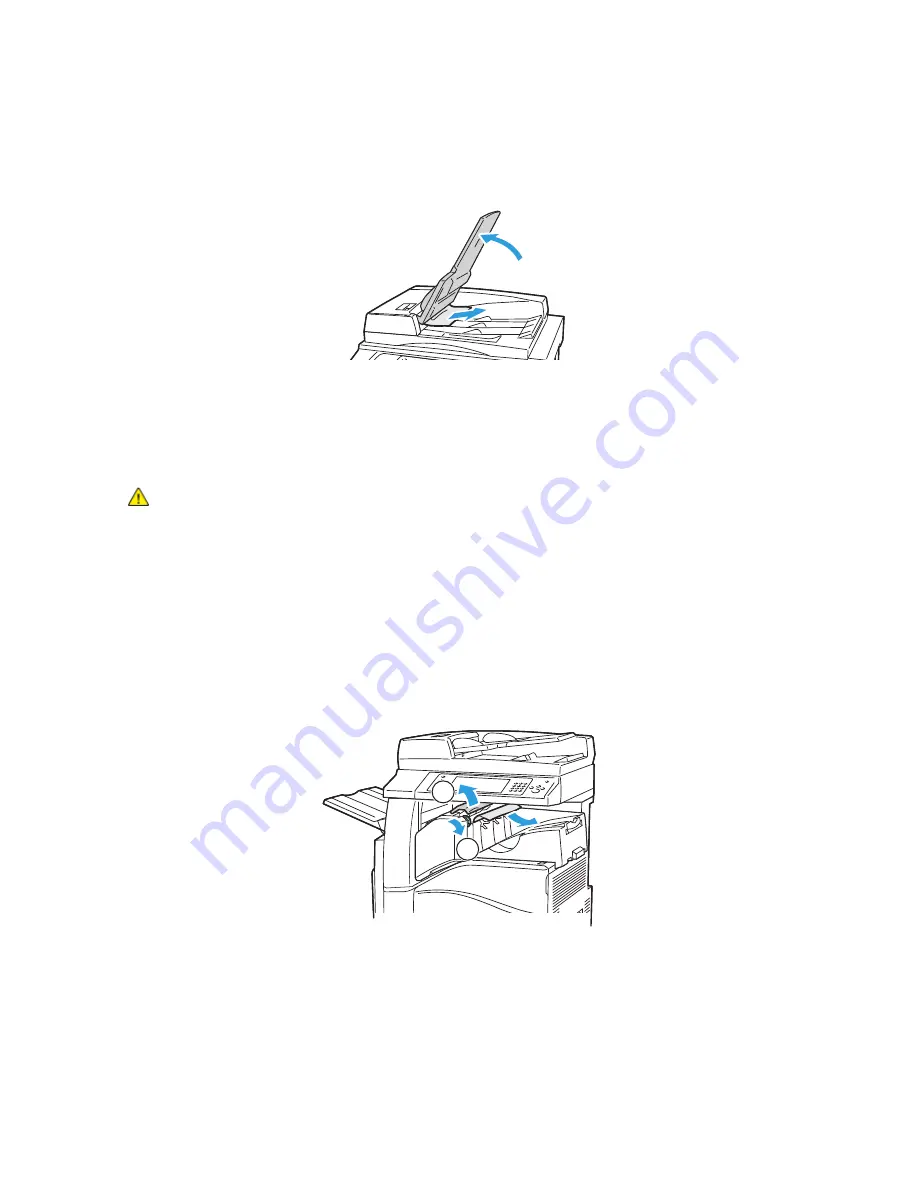

If the original is not visible when the document cover is opened, lift up the document feeder tray,

then remove the paper.

9.

Lower the document feeder tray.

10.

If the original is not wrinkled or torn, load it into the feeder again following the instructions on the

touch screen.

Note:

After clearing a document feeder jam, reload the entire document, including the pages already

scanned. The printer automatically skips the scanned pages and scans the remaining pages.

CAUTION:

Torn, wrinkled, or folded originals can cause jams and damage the printer. To copy torn,

wrinkled, or folded originals, use the document glass.

Clearing Jams in the Integrated Finisher

1.

Locate the Integrated Finisher mounted beneath the Scanner and Control Panel.

2.

Open the top cover of the finisher (1).

3.

Turn the green knob in the direction shown to remove the paper (2).

4.

Remove the paper by pulling it in the direction shown.

Note:

If the paper is torn, remove all torn pieces from the printer.

2

1

5.

Close the top cover of the Integrated Finisher.