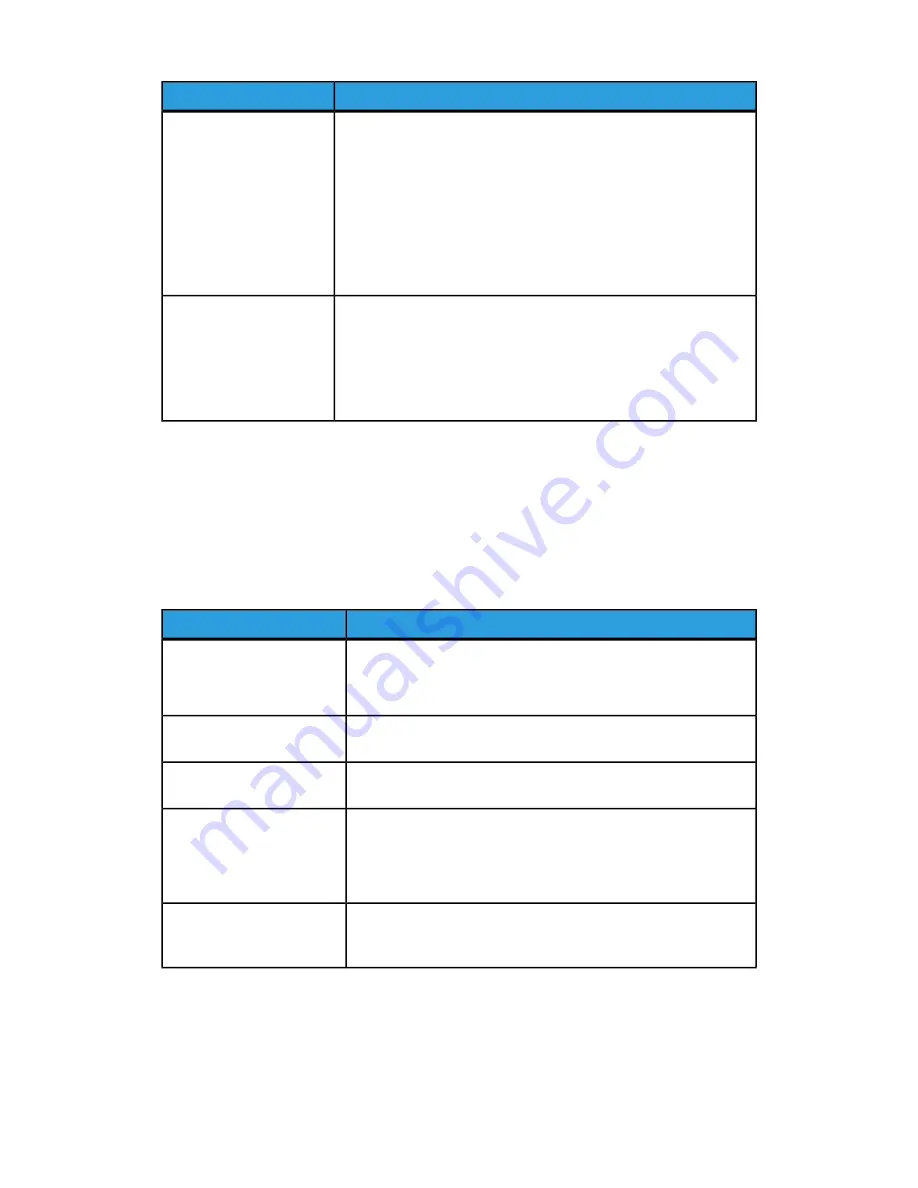

Remedy

Error

• Check for and remove loose pieces of media from inside the

scanner.

• Verify that the document is not curled, folded, wrinkled, or torn.

• Verify that the document is feeding correctly. Remove the doc-

ument and restart the job if necessary.

• Verify that suitable media is being used. Use only documents

printed on paper recommended by your Xerox Service Repres-

entative.

Jams occur frequently

• Press the green Power button to exit Power Save mode.

• Follow the specific instructions regarding faults or errors in the

software documentation.

• If the condition does not improve, contact your Xerox Service

Representative.

Status indicator light is lit.

Problems during Scanning

The following helps you solve problems encountered during scanning. Also refer to the

software documentation.

Table 7. Problems during Scanning

Remedy

Symptoms

• Open and close the scanner.

• Reboot the scanner and rescan.

Document doesn’t feed into

the scanner.

Make sure the document is at least 152 mm wide by 152 mm

long. Refer to

Loading Documents

.

Document doesn’t feed into

the scanner.

Make sure the scanning area is clean, and whenever it is soiled,

clean the Contact Image Sensor and scanner area.

The scanned image is dirty.

• Make sure the scanning area is clean, and whenever it is soiled,

clean the Contact Image Sensor and scanner area.

• Perform the normalization procedure. Refer to

Normalization

.

The scanned image has

black lines.

Verify that the document is inserted correctly, and if necessary,

correctly insert the document, with the edge of the document

aligned with the document guide.

The scanned images are

skewed.

Xerox

®

Wide Format 7742 Scan Solution

3-2

User Guide

Problem Solving