Phaser 6180 Color Laser Printer Service Manual

4-7

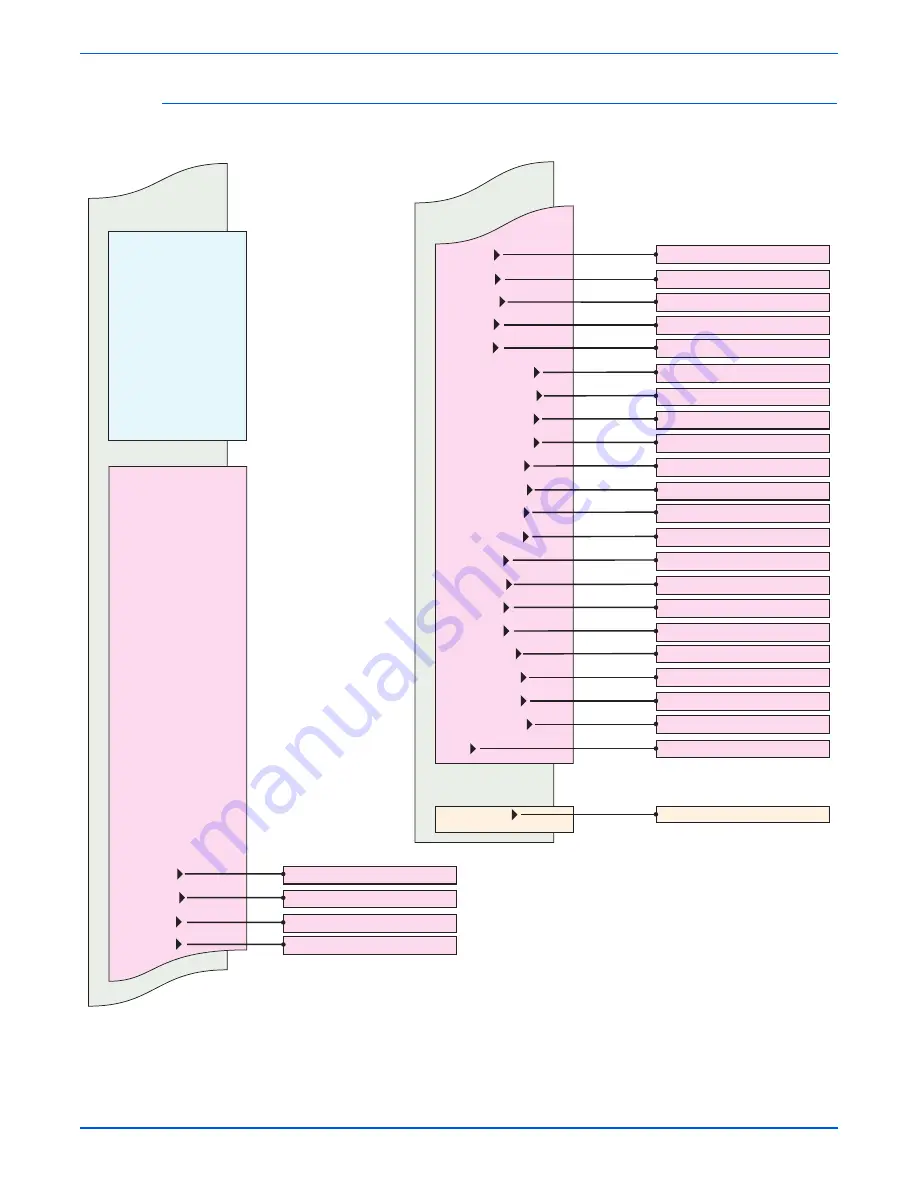

General Troubleshooting

Menu Map - Page 2

Test Print

Parameter

Parameter (Cont.)

No Image IOT

TestPat600 IOT

Grid 2 ESS

Cyan 20% ESS

Magenta 20% ESS

Yellow 20% ESS

Black 20% ESS

CMY 20% ESS

Gradation ESS

Exit Mode

Complete Exit

Slow Scan KtoP

Slow Scan 600M

Slow Scan 600Y

Slow Scan 600C

Slow Scan 1200M

Slow Scan 1200Y

Slow Scan 1200C

Fast Scan KtoM

Fast Scan KtoY

Fast Scan KtoC

Fast Scan MPT

Fast Scan Tray 2

Fast Scan Tray 3

Fast Scan Duplex

Fast Scan 2 KtoM

Fast Scan 2 KtoY

Fast Scan 2 KtoC

Life Y Toner

Life M Toner

Life C Toner

Life K Toner

Life DTB1

Life Fuser

Life Printer

Life DTB2

Life DTB3

Life YWasteToner

Life MWasteToner

Life CWasteToner

Life KWasteToner

Life Developer Y

Life Developer M

Life Developer C

Life Developer K

Life Y Drum

Life M Drum

Life C Drum

Life K Drum

Life MPT Feed

Life Tray2 Feed

Life Tray3 Feed

Life Duplex Feed

Life Y Toner: 0

Life YWaste Toner: 0

Life MWaste Toner: 0

Life CWaste Toner: 0

Life KWaste Toner: 0

Life Developer Y: 0

Life Developer M: 0

Life Developer C: 0

Life Developer K: 0

Life Y Drum: 0

Life M Drum: 0

Life C Drum: 0

Life K Drum: 0

Life MPT Feed: 0

Life Tray 2 Feed: 0

Life Tray 3 Feed: 0

Life Duplex Feed: 0

Ready*

Exit?

Life M Toner: 0

Life C Toner: 0

Life K Toner: 0

Life DTB1: 0

Life Fuser: 0

Life Printer: 0

Life DTB2: 0

Life DTB3: 0

s6180-455

*Prints current parameters

Summary of Contents for Phaser 6180

Page 1: ...Service Manual Phaser 6180 701P45793 Color Laser Printer ...

Page 2: ......

Page 14: ...xii Phaser 6180 Color Laser Printer Service Manual ...

Page 24: ...xxii Phaser 6180 Color Laser Printer Service Manual Contents ...

Page 234: ...3 108 Phaser 6180 Color Laser Printer Service Manual Error Messages and Codes ...

Page 318: ...4 84 Phaser 6180 Color Laser Printer Service Manual General Troubleshooting ...

Page 376: ...5 58 Phaser 6180 Color Laser Printer Service Manual Print Quality Troubleshooting ...

Page 386: ...6 10 Phaser 6180 Color Laser Printer Service Manual Adjustments and Calibrations ...

Page 500: ...110 Phaser 6180 Color Laser Printer Service Manual Service Parts Disassembly ...

Page 594: ...10 54 Phaser 6180 Color Laser Printer Service Manual Plug Jack and Wiring Diagrams ...

Page 606: ...A 12 Phaser 6180 Color Laser Printer Service Manual Reference ...

Page 615: ......

Page 616: ...701P45793 ...