4

25

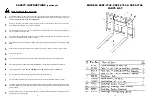

SAFETY INSTRUCTIONS

(continued)

Safety of the operator is one of the main concerns in designing and developing a new piece of equipment.

Designers and manufacturers build in as many safety features as possible. However, every year many

accidents occur which could have been avoided by a few seconds of thought and a more careful approach to

handling equipment. You, the operator, can avoid many accidents by observing the following precautions in this

section. To avoid personal injury, study the following precautions and insist those working with you, or for you,

follow them. Review the safety instructions with all users annually.

Never exceed the limits of a piece of machinery. If its ability to do a job, or to do so safely, is in question –

DON’T TRY IT.

Do not modify the equipment in any way. Unauthorized modification may impair the function and/or safety and

could affect the life of the equipment.

In addition to the design and configuration of this implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also

to Safety Messages and Operation Instructions in each of the appropriate sections of the Tractor, Skid Steer,

and Implement Manuals. Pay close attention to the Safety Signs affixed to the Tractor, Skid Steer, and the

Implement.

Replace any CAUTION, WARNING, DANGER or instruction safety sign that is not readable or is missing.

Location of such safety signs is indicated in this booklet. Do not paint over, remove or deface any safety signs

or warning signs on your equipment. Observe all safety signs and practice the instruction on them.

Never use alcoholic beverages or drugs which can hinder alertness or coordination while operating this

equipment. Consult your doctor about operating this machine while taking prescription medications.

This equipment is dangerous to children and persons unfamiliar with its operation. The operator should be a

responsible adult familiar with farm machinery and trained in this equipment’s operations. Do not allow per-

sons to operate or assemble this unit until they have read this manual and have developed a thorough

understanding of the safety precautions and of how it works.

EQUIPMENT SAFETY GUIDELINES

Know your controls and how to stop skid steer, tractor, engine, and loader quickly in an emergency. Read this

manual and the one provided with your tractor or skid steer.

Only use a power unit equipped with a ROPS cab or rollover protective structure. Keep foldable ROPS sys-

tems in “locked up” position at all times. Keep seat belt fastened.

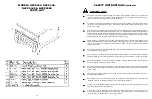

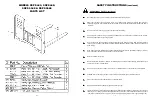

MODELS JDPF-5442, JDPF-5448 & JDPF-5460

PARTS LIST