10

19

SAFETY INSTRUCTIONS

(continued)

Following operation or when unhooking, stop the tractor, set the brakes, shut off the engine, relieve all hydraulic

pressure and remove the ignition keys.

Store the unit in an area away from human activity. Do not permit children to play on or around the stored unit.

Do not park equipment where it will be exposed to livestock for long periods of time. Damage and livestock

injury could result.

Make sure all parked machines are on a hard, level surface and engage all safety devices. Storage location

should be level and solid to make connecting and unconnecting to power unit easy.

If blocking is used, make sure it is solid and secure before leaving area.

STORAGE SAFETY

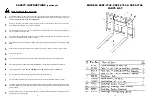

Keep safety signs clean and legible at all times.

Replace safety signs that are missing or have become illegible.

Replaced parts that displayed a safety sign should also display the current sign.

Safety signs are available from your Distributor or Dealer Parts Department or the factory.

Be sure that the installation area is clean and dry. Be sure temperature is above 50°F (10°C).

Decide on the exact position before you remove the backing paper.

Remove the smallest portion of the split backing paper. Align the sign over the specified area and carefully

press the small portion with the exposed sticky backing in place.

Slowly peel back the remaining paper and carefully smooth the remaining portion of the sign in place. Small

air pockets can be pierced with a pin and smoothed out using the piece of sign backing paper.

How to Install Safety Signs:

SAFETY SIGNS

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped out

by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention

are dependent upon the awareness, concern, judge-

ment, and proper training of personnel involved in the

operation, transport, maintenance and storage of

equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be that

kind of operator.

The operator is responsible for the safe operation of

this equipment. The operator must be properly trained.

Operators should be familiar with the equipment, the

tractor, and all safety practices before starting operation.

Read the safety rules and safety decals on pages 3

through page 11.

OPERATING INSTRUCTIONS

■

■

Do not operate this product until you have posi-

tive indication that this attachment is securely

mounted to the loader. Failure to install lock pins or

have the latching mechanism engaged could result

in injury or death.

■

■

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely fas-

tened. Falling off power unit can result in death from

being run over or crushed. Keep foldable ROPS sys-

tems in “locked up” position at all times.

■

■

Pallet Forks are NOT to be used for large round

bales, as this would create a hazardous condition.

■

■

Do NOT exceed loader or attachment lift capacity.

■

■

Rear ballast is required to ensure 25% of gross

vehicle weight is transferred to the rear axle.

Attachment and load must be included as weight.

Adequate rear weights are required to counterbal-

ance maximum loader capacity and safe loader oper-

ation. Weight can be added as rear tire liquid, rear

wheel weights, rear axle weights and/or three point

hitch mounted ballast or implement. Ballasting will

vary with tractor and loader attachment. Refer to the

Tractor manual for recommended ballasting.

■

■

Never allow children or untrained persons to

operate equipment.

■

■

Keep bystanders away from equipment.

■

■

Never allow riders on power unit or attachment.

Beware of low electrical wires when loader is

raised. Serious injury or death can result if contact is

made.

Do not leave the operator’s seat if any part of the

power unit, loader or attachment contacts electric

lines.

■

■

Avoid carrying loose or shiftable loads. Falling

items could cause injury.

■

■

Beware of lift clearance when raising loader to

maximum height.

■

■

Always stop the power unit, set brake, shut off

engine, remove key, and lower loader to ground

before attempting to service. Never leave equipment

unattended with engine running.

OPERATION

——————————————————

Be sure tractor or skid steer is properly counter-

balanced with weights before attempting to lift any load.

Make sure fork latch is properly engaged.

Using the bucket tilt cylinders, adjust the angle of the

fork tines so they are parallel with the ground.

Adjust height of fork tines to enter the pallet to be

handled. Always keep the load or pallet as close to the

forklift main frame as possible.

Make sure weight of load is centered between the

forks.

Make sure all operators have read the Owner’s

Manual and are familiar with the instructions and the safe-

ty rules of operation.

WARNING

WARNING

CAUTION

DANGER