16

13

INSTRUCTIONS

(continued)

INSTRUCTIONS

(continued)

MODEL PF-448

——————————————————

The Universal model PF-448 Pallet Fork attachment is

designed to fit most double-cylinder front end loaders

with a load-arm center distance of 52 inches or less.

Optional brackets are available to fit both pin-on and

some popular quick coupler front-end loaders. Brackets

must be ordered with the pallet fork attachment to mount

on your loader.

The Universal Pallet Fork can also be used on the rear

3 pt. Cat. II hitch with pin-on brackets and the Optional

#831815 Toplink Bracket.

With the optional #830358 Bushing Kit, a Cat. II Quick

Hitch may be used. (Pin-on brackets and toplink bracket

required.)

The model PF-448 with 48” solid pallet forks can han-

dle loads up to 4,000 lbs. Load ratings are figured with the

load about 24” in front of the fork lift frame and evenly

distributed between the two fork tines.

Install the two backstop weldments on the top crossbar

(see page 21).

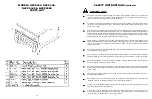

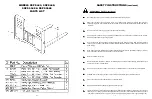

ASSEMBLY – TRACTOR LOADERS

PIN ON ATTACHMENT

——————————————————

Preview the assembly instructions and the exploded

views of the pallet fork in your operator’s manual and

become familiar as to how the parts or assemblies go

together. For model PF-448, see page 21.

Assemble the two lift brackets on the main frame with

the

5

/

8

” x 3” I.D. U-bolts. Leave the U-bolts loose.

NOTE: The optional lift channel brackets are supplied

with 1” diameter pins to fit your loader. If your loader

requires 1

1

/

8

” pins, it will be necessary for the hole diam-

eter in the channel brackets to be drilled out to 1

5

/

32

”

(1.156”) and ask your dealer to order 1

1

/

8

” diameter pins.

The 1

1

/

8

” pins are part #830318. Be sure to indicate if two

or four 1

1

/

8

” pins are required.

If your loader requires 1

1

/

4

” diameter pins, please ask

your dealer to order adapter bushings (part #830319). Be

sure to indicate how many adapter bushings are required.

NOTE: The Ford (New Holland) models 7109, 7209,

7210, 7309, 7310 and 7410 Pin Type Loaders require

special brackets. Also, Rhino (Alamo) models 2410Q and

2491Q. Order #830330 bracket kit.

NOTE: For loaders that require brackets that provide

additional roll back, order #830335 (1” pins).

Connect the above assembly to the loader arms using

the bottom hole in the channel and attach the upper con-

trol cylinder to the top hole in the lift channels. Center the

main frame (side to side) with your loader arms and

tighten the four (4)

5

/

8

” x 3” U-Bolts.

The lower hole positions in the lift channels can be used

to obtain more angle movement. However, if the frame

becomes too parallel with the loader lift arms, the loader

may not have enough power (mechanical advantage) to

bring the frame back.

NOTE: Generally, it is not recommended to have the tilt

cylinders located any closer than 10-12 inches to the

main loader lift arms. Check the spacing of mounting

pins on your loader bucket and use this as a guide.

NOTE: If tilt cylinders are located too close to the loader

arms, they may go “over center” when fully extended. If

this happens, damage may occur to the cylinders and/or

mounting brackets.

For first time installation, read the instructions for

mounting your pallet fork attachment on your front loader

or skid steer. (See pages 13-16.)

Remove the bucket from your front end loader. Check

your loader to make sure it is in good working order.

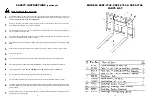

FORK TINE INSTALLATION

——————————————————

With loader arms lowered and completely rolled back,

shut down the power unit following the safety shutdown

procedure for your unit. Ensure that the locking assembly

on the tine is in the unlocked (UP) position. Place the top

of the fork on the top rail in the middle of the frame and

then rotate down. Slide the fork to the side to seat it on

the frame and, using the locking assembly that is on your

tine, lock in place. Install the following tine(s) in the same

fashion. Make sure the locking assembly has been set

into a notch on the top rail and therefore securing the tine

to the frame.

NOTE: Smearing a light coat of grease on the main frame

rails will make adjusting the fork width easier.

IMPORTANT: Keep forklift tines adjusted to maximum

width for better load stability.

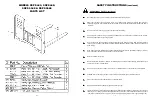

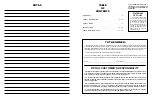

MODELS GLPF-442/448/5548/5560

ATTACHMENT TO PRIME MOVER

——————————————————

The Models GLPF-442, GLPF-448, GLPF-5548, and

GLPF-5560 are specifically designed for tractor front

loaders with the Euro or Global bucket quick-change

system.

The Models GLPF-442/448 have a load rating of 4,000

lbs.

The Models GLPF-5548 and GLPF-5560 have a load

rating of 5,500 lbs.

NOTE:

The instructions for the JDPF-H480 Models are similar

to the Euro/Global ones.

ATTACHING

1. To prepare the loader for attachment, pull and rotate

handle to open latch (A).

2. Extend attachment cylinders to angle attaching

brackets forward.

3. Drive forward, adjusting loader height and position

until the bar (B) is under hooks (C) and tabs (D) are

on the center side of the hooks.

4. Raise loader and retract tilt cylinders until latch

closes.

5. Lower attachment and shut off engine. Installation is

now complete.

DETACHING

1. Lower pallet fork to ground. Place the transmission in

PARK and shut off engine and remove key.

2. Pull and rotate handle to open latch (A).

3. Start tractor and lower attachment to ground. Slowly

extend bucket tilt cylinders until loader clears the latch

plate. Lower loader until bar clears the hooks.

4. Drive tractor in reverse until loader is clear of the

attachment.

OBEY ALL SAFETY WARNINGS!

CAUTION!

ALWAYS CHECK LATCH PINS

BEFORE TILTING OR OPERATING

ANY ATTACHMENT.

NOTE: Latch automatically closes on some global

carrier. Always check latch pins.